The Department of Safety and Quality offers project elaboration and professional consultations in the following areas:

Elaboration of comprehensive documentation according to the requirements of Act no. 128/2015 Coll. (SEVESO III) as amended and its implementing regulations for both new project units and existing facilities.

This documentation contains of:

1. Company categorization.

2. Major industrial accident prevention program.

3. Safety management system.

4. Risk assessment and evaluation.

5. Emergency plan.

6. Safety report.

For small businesses, we provide documents for spatial planning documentation (zoning decision, EIA) preliminary risk assessment for the purpose of issuing zoning and building permits. We provide training for emergency specialists and emergency technicians.

Elaboration of a document according to the Regulation of the Government of the Slovak Republic no. 393/2006 Coll. (ATEX), which regulates the minimum requirements for ensuring safety and health at work in an explosive environment.

The document contains:

1. A list of stored and handled flammable substances which may create an explosive atmosphere with air.

2. Effective sources of initiation

3. Explosion risk assessment

4. Zone classification

5. Proposed measures.

The department offers consultations and methodologies necessary for the implementation of Act no. 45/2011 Coll. on critical infrastructure.

Development of documentation to ensure operations within the critical infrastructure. This document is prepared in accordance with European legislation and serves to ensure the operability of companies in crisis situations. Specific documents in crisis planning are business continuity plans. The task of business continuity plans is to create technical - organizational measures in companies, operations to manage crisis situations. It is possible to certify the management of these procedures according to ISO 22301:2019.

Continuity plans include:

1. Analytical analysis of external and internal threats, including asymmetric threats (terrorism, biological and social threats). The threats catalog applied in the EU is used.

2. Risk assessment is performed on the basis of a process model.

3. Proposals for measures with regard to the requirements of the European Union, the Slovak Republic and the company (especially for oil and gas pipelines).

Creating a model for risk management of piping systems based on integrity requirements - risk matrix, hazard specification, weighting factors, both for the purpose of their design and construction, and for the purpose of diluting their operation and maintenance.

Design of a concept for dynamic segmentation of piping systems based on the results of risk assessment.

Quantification of the range of safety zones for defined / segmented piping systems.

Application of methods and tools in risk assessment:

• For technological units, equipment with regard to the characteristic features of the equipment - technical risks.

• Risk assessment at workplaces in the work process - professional risks.

• Assessment of residual risks in order to meet the conformity requirements of machinery.

System implementation - complex activities associated with employee training, creation of documentation.

Consulting - consulting and professional supervision in the whole spectrum of activities within the implementation of the system or at full operation of the system.

Internal audits - verification of the system in the process of its implementation and after implementation.

Systems according to: ISO 45001, ISO 22301.

System implementation - complex activities associated with employee training, creation of documentation.

Consulting - consulting and professional supervision in the whole spectrum of activities within the implementation of the system or at full operation of the system.

Internal audits - verification of the system in the process of its implementation and after implementation.

Systems according to: ISO 9001, IATF 16949.

Implementation of an integrated system - complex activities associated with employee training, creation of documentation.

Consulting - advice and professional supervision in the whole spectrum of activities within the implementation of the system / systems or in their full operation. Processing and preparation of KPIs for the purpose of process evaluation.

Internal audits - verification of the system / systems in the process of their implementation and after implementation.

Systems according to: ISO 9001, IATF 16949, ISO 45001.

Method of integration: implemented on an existing system, integration of newly created ones

Department of Safety and Quality for Maintenance Management of Technical Equipment provides the following tasks for practice:

• Risk assessment of mechanical - technical equipment in order to determine the actual state of equipment, especially application of RCM, RBI in petrochemical, chemical and selected plants.

• Consultation and preparation of TPM implementation.

• Design of a maintenance strategy based on the identification of equipment conditions. Identification is performed by standard risk assessment methods (also quantitative in the case of RBI): analysis of critical devices (A, B, C), application of FMEA / FMECA methods, outputs in the form of strategies and types of maintenance for the analyzed equipment, benchmarking (KPI) and maintenance audits.

Training courses:

Training focused on maintenance requirements of the RCM, RCM Cost, TPM and RBI concepts.

Elaboration of a functional model of predictive maintenance, specification of the connection with other processes so that the overall diagnostic of equipment fulfills its function of quality, economics and safety. Measurement and analysis of machines and standing equipment, evaluation of technical condition. Condition evaluation, recommendations and suggestions for repair.

1. Proposal for the division of machinery according to importance in operating conditions - criticality analysis of equipment.

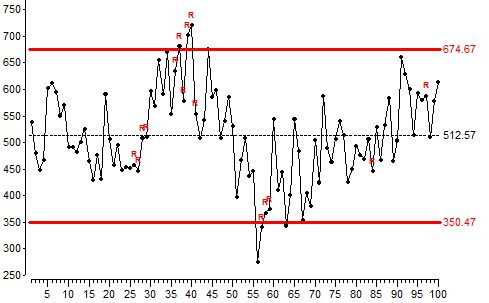

2. Design of time intervals for vibration measurement and analysis. Harmonization of evaluation tables for vibration measurement and analysis based on ISO 13373.

3. Design of vibrodiagnostic procedures and records of values during inspections and their evaluation while respecting all requirements of ISO 13373.

4. Design of analysis of slow-running machines with speeds from 0.1 to 600 min-1.

2008, 9 – Slovnaft (TUV Rheiland) Implementácia RCMCost a RBI

2005-2008, SPP distribúcia: Model PIMS

2008: eustream, Implementácia RCM , Vývoj štruktúry KPI

2010, Ford Getrag: Implementácia TPM

2006 – 2010, USS: ZPH

Realized commercial contracts

| Name of the contract | Client |

| ZoD 34/103401/2020 | P.B.I., s.r.o, Senica |

Proposal of risk assessment methodology in connection with pandemic threats in industrial enterprises falling into categories A, B in the Act of the National Council of the Slovak Republic no. 128/2015 Coll. |

|

| ZoD 15/103401/2019 | Duslo, a.s. |

Elaboration of an update of the Safety Report for the company Duslo, a.s., Bratislava locality in accordance with the assignment to tender no. ON / MV / 01/2019 and CP "Security Report-Update", dated 14.03.2019 |

|

| ZoD 14/103401/2019 | U. S. Steel Košice, s.r.o. |

Elaboration of explosion protection documentation O2, C2H2 in accordance with Annex No.1 |

|

| ZoD 43/103401/2018 | U. S. Steel Košice, s.r.o. |

Risk analysis and assessment for the project of oxygen interconnection from ASU 5 & 6 to VP. |

|

| ZoD 28/103401/2018 | U. S. Steel Košice, s.r.o. |

Technical assistance - update of the processed "Explosion protection documentation" based on the requirements of DZ Energetika. |

|

| ZoD 27/103401/2018 | Ferroenergy, s.r.o. |

Technical assistance - update of the processed "Explosion protection documentation" for Ferroenergy, ltd. based on new requirements. |

|

| ZoD 21/103401/2018 | Unomedical s.r.o. |

Identification of electric shock hazards for Unomedical, s.r.o. |

|

| ZoD 15/103401/2016 | U. S. Steel Košice, s.r.o. |

"Analysis and assessment of Major industrial accidents risk in USSK in accordance with the requirements of new legislation" |

|

| ZoD 40/103401/2015 | Ford Getrag Transmision |

Operating instructions and Explosion protection documentation |

|

| ZoD 31/103401/2015 | Ford Getrag Transmision |

| Analysis of documentation and elaboration of an environmental protocol for the HT Department (heat treatment) and the Technical Building. |

|

| ZoD 6/103401/2014 | Transpetrol, a.s. |

Update of safety documentation in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll.as well as the requirements of Directive 2012/18 / EU (SEVESO III) in TRANSPETROL, a.s., PS1, PS2, PS3, PS4, PS5. |

|

| ZoD 59/103401/2013 | Transpetrol, a.s. |

Update of safety documentation in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. as well as the requirements of Directive 2012/18 / EU (SEVESO III) in TRANSPETROL, a.s., PS1, PS2, PS3, PS4, PS5. |

|

| HZ 59/2013 | Transpetrol, a.s. |

Safety report update - PS4, OSR |

|

| HZ 02/2013 | U. S. Steel Košice, s.r.o. |

Training - Ensuring equipment reliability. |

|

| HZ 37/2012 | Transpetrol, a.s. |

Safety Report Update - PS1 Budkovce |

|

| HZ 30/2012 | U. S. Steel Košice, s.r.o. |

Development of materials for critical infrastructure risk analysis |

|

| HZ 8/2012 | Whirlpool Slovakia,s.r.o. |

Creating software for Behaviour based safety |

|

| HZ 25/2012 | U. S. Steel Košice, s.r.o. |

Revision of explosion protection document on DZ- Hot rolling mill |

|

| HZ 2012 | U. S. Steel Košice, s.r.o. |

Creating software for the Behavior based safety project |

|

| HZ 6/2012 | U. S. Steel Košice, s.r.o. |

Analysis and assessment of the extent of blast furnace gas leakage |

|

| HZ 2011 | Whirlpool Slovakia,s.r.o. |

Risk analysis Stage 2 |

|

| HZ 2011 | Whirlpool Slovakia,s.r.o. |

Risk analysis Stage 1 |

|

| HZ 36/2011 | U. S. Steel Košice, s.r.o. |

Risk assessment in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 2011 | U. S. Steel Košice, s.r.o. |

Risk assessment - Collection of converter gas from Steelworks I. for USSK |

|

| HZ 54/2011 | Transpetrol, a.s. |

Graphic materials update of of ATEX zones in accordance with the document on explosion protection for Transpetrol company |

|

| HZ 26/2011 | U. S. Steel Košice, s.r.o. |

Update of Explosion protection documentation DZ - Blast furnaces |

|

| HZ 23/2011 | U. S. Steel Košice, s.r.o. |

Risk assessment according to Act 261/2002 Coll. on the prevention of Major industrial accidents for the desulphurisation of raw coke oven gas |

|

| HZ 22/2011 | U. S. Steel Košice, s.r.o. |

Safety Report Update U.S.Steel KE |

|

| HZ 2010 | Ford Getrag Transmision |

Implementation of TPM in Ford Getrag Transmission |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Update of Explosion protection documentation DZ Energetika |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of Explosion protection documentation for U.S.SERVIS, s.r.o |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Revision and harmonization of Explosion protection documentation DZ Koksovňa |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of Explosion protection documentation REFRAKO, s.r.o |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of Explosion protection documentation for LABORTEST, s.r.o |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of Explosion protection documentation for VULKMONT, a.s |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of Explosion protection documentation for OBAL - Servis |

|

| HZ 2010 | U. S. Steel Košice, s.r.o. |

Elaboration of a proposal min. the cross-section of the pipeline for the newly designed liquid NH3 route and the proposal of safety measures |

|

| HZ 70/2010 | Transpetrol, a.s. |

Update of risk analysis for explosion protection |

|

| HZ 38/2010 | U. S. Steel Košice, s.r.o. |

Study of variants of the technological solution of ammonia technology in order to achieve the acceptability of social risk in the USSK |

|

| HZ 108/2009 | CMF Slovakia, s.r.o |

Special consultations required for the implementation of the quality management system according to EN ISO 9001: 2008 - Engineering activities and related technical consultancy |

|

| HZ 78/2009 | Transpetrol, a.s., Budkovce |

Update of the emergency plan of operation of PS1 Budkovce (Transpetrol) in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 76/2009 | Transpetrol, a.s., Budkovce |

Update of risk assessment for PS1 Budkovce plant (Transpetrol) according to the requirements of the Act on |

|

| HZ 79/2009 | Transpetrol, a.s., Budkovce |

Update of documents for the protection of the population of the PS1 Budkovce plant (Transpetrol) in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 77/2009 | Transpetrol, a.s., Budkovce |

Update of the safety report of PS1 Budkovce plant (Transpetrol) in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 57/2009 | Transpetrol, a.s., Budkovce |

Study of methods and trends for measuring oil flow on the oil pipeline network |

|

| HZ 54/2009 | Kybernetika s.r.o |

Residual risk assessment, analysis of technical documentation and conformity assessment for selected technological lines of the company. IEE Sensing Slovakia s.r.o |

|

| HZ 31/2009 | Risk Consult,s.r.o |

|

|

|

| HZ 33/2007 | U. S. Steel Košice, s.r.o. |

Processing of documentation for oxygen apparatus No.9. |

|

| HZ 51/2008 | Slovenské elektrárne, a.s. |

Elaboration of risk analysis for the process of disassembly, repair and assembly of reactor lid accessories. |

|

| HZ 19/2008 | SPP, a.s., Bratislava |

Conditions for the construction of gas pipelines for the purpose of providing building permits. |

|

| HZ 42/2007 | SPP, a.s., Bratislava |

|

Assessment of the reliability of selected equipment based on FMEA analysis. |

|

| HZ 53/2008 | U. S. Steel Košice, s.r.o. |

Risk assessment of major industrial accidents. |

|

| HZ 20/2008 | U. S. Steel Košice, s.r.o. |

Proposal of technical measures to reduce the social risk to the risk acceptable for the ammonia economy facility and its related infrastructure containing HN3. |

|

| HZ 28/2008 | U. S. Steel Košice, s.r.o. |

Risk assessment for expenditure plant T1000. |

|

| HZ 48/2007 | Carmeuse Slovakia,s.r.o., Košice |

Coaling of rotary furnaces. Creation and elaboration of a safety program, risk assessment, elaboration of an emergency plan, elaboration of a document on explosion prevention. |

|

| HZ 44/2007 | Carmeuse Slovakia,s.r.o., Košice |

Coaling of rotary furnaces Elaboration of a report on the categorization of the company in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 45/2007 | Tepláreň Košice, a.s. |

General technical diagnostics of a ball mill focused on measuring, evaluating and preparing a report on running diagnostics. If errors are found, a proposal for correction. |

|

| HZ 20/2007 | U. S. Steel Košice, s.r.o. |

Evaluation of the occurrence of serious industrial accidents of the new building Galvanizing line 3 in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 8/2007 | U. S. Steel Košice, s.r.o. |

Evaluation of the occurrence of major industrial accidents of the building Oxygen apparatus No. 9 in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 78/2006 | SEZ Krompachy, a.s. |

Methods applied in quality planning and product implementation. |

|

| HZ 52/2006 | U. S. Steel Košice, s.r.o. |

Expert assessment of explosion risks according to NV SR No. 493/2002 Coll. |

|

| HZ 47/2006 | P.B.I., s.r.o., Senica |

Safety and reliability management conditions based on the identification and assessment of risk factors. |

|

| HZ 30/2006 | SPP, a.s., Bratislava |

Safety and reliability management conditions based on the identification and assessment of risk factors. |

|

| HZ 38/2006 | Pivovary Topvar, a.s., Topoľčany |

|

Elaboration of Explosion protection documentation according to NV SR No. 493/2002 Coll. |

|

| HZ 28/2006 | CORINEXGROUP, a.s., Bratislava |

Elaboration of chapters within the project "Analysis of the possibilities of monitoring the integrity of the pipeline in the conditions of the SPP of the Transit division. |

|

| HZ 15/2006 | Interport Servis,s.r.o., Košice |

Categorization for magnesium storage in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 14/2006 | U. S. Steel Košice, s.r.o. |

Expert assessment of explosion risks according to NV SR No. 493/2002 Coll. |

|

| HZ 12/2006 | KYBERNETIKA, s.r.o., Košice |

Development of an algorithm for deciding whether the assessed area is risky or non-risky. |

|

| HZ 5/2006 | P.B.I., s.r.o, Senica |

Processing of data analysis for solving the problem of elaboration explosion protection documentation according to STN EN 60079-10, STN EN 60079-20. |

|

| HZ 69/2005 | MOLEX Slovakia,s.r.o., Košice |

Categorization and preliminary risk assessment for Molex Slovakia, s.r.o. in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 20/2005 | SPP, a.s., Bratislava |

Integrity management conditions based on the identification and evaluation of risk factors in SPP, a.s. |

|

| HZ 16/2005 | NDS, a.s., Branisko |

Creation of the organizational and management system of the Branisko Tunnel operation. |

|

| HZ 15/2005 | NDS, a.s., Branisko |

Performing an analysis of the current state of operation of the Branisko Tunnel. |

|

| HZ 11/2005 | SPP, a.s., Bratislava |

Statistical evaluation of diagnostic measurements in order to improve maintenance while taking into account risk factors in operation. |

|

| HZ 5/2005 | P.B.I., s.r.o, Senica |

Advisory and consulting activities in the preparation of risk assessment in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 40/2004 | U. S. Steel Košice, s.r.o. |

Risk assessment and preparation of documents in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 21/2004 | EVO, a.s., Vojany |

Risk assessment in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 20/2004 | U. S. Steel Košice, s.r.o. |

Assessment of the impact of the new dynamoline line No. 3 in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 12/2004 | U. S. Steel Košice, s.r.o. |

|

|

|

| HZ 1/2004 | P.B.I., s.r.o, Senica |

|

|

|

| HZ 36/2003 | Vegum, a.s., Vestenice |

Preparation of safety audit in accordance with the requirements of the OHSAS 18 001 standard. |

|

| HZ 32/2003 | EVO, a.s., Vojany |

Elaboration of a security program in according to the requirements of the Act on Prevention of Major industrial accidents No. 261/2002 Coll. |

|

| HZ 13/2003 | Vihorlat, s.r.o., Snina |

Elaboration of a preliminary design of an ergonomic crane cab. |

|

| HZ 17/2003 | Mecom, a.s., Humenné |

Preparation of preliminary risk assessment |

|

| HZ 31/2002 | BSH DRIVES and PUMPS, s.r.o., Michalovce |

Elaboration of safety audit for BSH DRIVES and PUMPS, s.r.o .. |

|

| HZ 26/2001 | Chemko, a.s., Stražske |

Elaboration of an emergency plan and elaboration of a risk assessment based on SEVESO II. |

|

| HZ 4/2001 | Chemosvit, a.s., Svit |

Elaboration of a Pilot project for a comprehensive safety management system within integrated approaches based on the ISO 18 001-02 proposal. |

Scientific research activity – VEGA, KEGA

KEGA č. 026TUKE-4/2023

Doba riešenia: 2023-2025

Zodpovedný riešiteľ: Ing. Anna Vrabeľová, PhD., MBA

Podpora rozvoja vedomostí v oblasti implementácie požiadaviek systému manažérstva kvality pre letecký, vesmírny a obranný priemysel.

Anotácia (podstata) vedeckého projektu:

Súčasná geo-politická situácia a z nej vychádzajúca potreba okamžitej reakcie na daný stav dáva priestor organizáciám na vývoj a výrobu nových komponentov, po ktorých vzrastá dopyt. Oblasť letectva, astronautiky ako aj obrany je technologicky riadený priemysel, ktorý je charakteristický automatizáciou a digitalizáciou a ktorý integruje komplexné výrobné systémy a procesy s vysokými nárokmi na kvalitu ako aj bezpečnosť. Aj tie najmenšie nedostatky v poskytovaných produktoch alebo službách môžu mať v tejto oblasti fatálne následky. Vzhľadom k súčasnej situácii je predpoklad, že čoraz viac organizácií bude v budúcnosti do svojho portfólia pridávať komponenty a produkty, ktoré budú v tejto oblasti žiadané. Súčasná platná legislatíva EÚ určuje konkrétne požiadavky na výrobu komponentov pre tento druh priemyslu, avšak vstupnou bránou pre vytvorenie odberateľsko – dodávateľského reťazca je naplnenie požiadaviek na kvalitu daných zákazníkom. Pre oblasť zabezpečenia požiadaviek na kvalitu existuje od roku 1987 norma ISO 9001 Systém manažérstva kvality - Požiadavky, ktorá doteraz prešla niekoľkými revíziami. V súčasnosti je platná 5ta revízia, ktorá bola publikovaná v roku 2015 označovaná v rámci SR ako STN EN IS0 9001:2016. Zásadnou črtou tejto normy je štruktúra označovaná ako HLS (High Level Structure), ktorá je zakomponovaná aj do normy AS9100 - "Požiadavky systému manažérstva kvality pre letecký, vesmírny a obranný priemysel", ktorá je na Slovensku vydaná ako norma s označením STN EN 9100. Cieľom tohto projektu je implementovať požiadavky normy STN EN 9100 do výrobných procesov realizovaných v Prototypovom a Inovačnom Centre Strojníckej fakulty TUKE (PAIC SjF TUKE), ktoré sa zaoberá výskumom ale aj výrobou prototypov a sériových komponentov.

V súlade s tematickou oblasťou tejto výzvy - Nové technológie, metódy a formy vo vzdelávaní sa tak vytvorí priestor pre študentov na získanie vedomostí, ktoré môžu neskôr uplatniť v praxi. Na realizácii tohto projektu sa budú podieľať zamestnanci Katedry bezpečnosti a kvality produkcie (KBaKP). Takmer všetci riešitelia majú s implementáciou manažérskych systémov skúsenosti a dokážu výsledky tohto projektu adekvátne pretransformovať do edukačného procesu odborných predmetov a prispieť tak ku kreovaniu nového plánovaného programu 2. stupňa vysokoškolského štúdia: Kvalita a bezpečnosť.

Anotácia projektu v anglickom jazyku

The current geo-political situation and the resulting need for an immediate response to the situation gives space for organizations to develop and produce new components, for which demand is growing. The field of aviation, space and defense is a technologically controlled industry, which is characterized by automation and digitization and which integrates complex production systems and processes with high demands on quality and safety as well. Even the smallest non-conformities in the products or provided services can have fatal consequences in this area. Given the current situation, it is expected that more and more organizations will add components and products to their portfolio in this area in the future. Current EU legislation sets out specific requirements for the production of components for this type of industry, but very important aspect is a creation of a customer - supply chain and the fulfillment of quality requirements given by customers. For the area of quality requirements assurance, there exists ISO 9001 "Quality Management System - Requirements" since 1987, which has so far undergone several revisions. Currently, the 5th revision is valid, which was published in 2015 and referred to in the Slovak Republic as STN EN IS0 9001:2016. The main element of this standard is the structure referred to as HLS (High Level Structure), which is also incorporated

into the standard AS9100 - "Requirements of the quality management system for the aviation, space and defense industry", which is issued in Slovakia as the standard STN EN 9100. The aim of this project is to implement the requirements of the STN EN 9100 standard into production processes in the Prototype and Innovation Center of the Faculty of Mechanical Engineering TUKE (PAIC FME TUKE), which deals with research but also production of prototypes and serial components. Due to the thematic area of this call - New technologies, methods and forms in education, the project will create a space for students to achieve knowledge that they can later apply in practice. Most of the employees of the Safety and Quality Department (S&Q) have experience with the implementation of management systems. They adequately can transform the results of this project into the educational process of subjects and thus contribute to the creation of a new planned 2nd degree study program Quality and Safety.

ID: 22230024

Doba riešenia: 2023-2024

Ing. Anna Vrabeľová, PhD., MBA

Improving quality management teaching in the era of Industry 4.0

Anotácia (podstata) vedeckého projektu:

The cooperation of technical and economic universities from Czechia, Poland, and Slovakia will cover the study of the needs of the Industry 4.0 enterprises, acquiring new competencies related to modern quality management by lecturers, and creating new teaching programs that will lead to better preparation of graduates to current requirements of the V4 countries industry.

KEGA 019TUKE-4/2020

2020-2022

doc. Ing. Štefan Markulik, PhD.

Application-oriented education in the field of implementation of the requirements of the ISO 9001: 2015 standard

Abstract (essence) of the scientific project:Education, research and development are key supportive pillars of economic development and competitiveness in the EU. High demand for graduate´s competences require universities to respond to this by adjusted education. This competence involves theoretical preparation as well as practical skills to apply the acquired knowledge. Requirements for the competence of graduates in this way require a fundamental change in the approach in provided education, which includes the adoption of flexible learning new methods and tools besides the structural content. The presented project is focused on increasing the competence of students / graduates for their immediate integration to the work process. Their training in higher education can be a cost saving for their further training from the employer. The aim of this project is to create educational material added by a practical handbook, which will help students / graduates and also people from industry to better understand implementation of the quality management system. At present, there is no organization operating in a global market that does not have quality elements in its management. This was the major impulse for the decision to prepare a project that would transform the knowledge and skills of project leaders in the area of quality and other interdisciplinary areas into one part.

KEGA 015TUKE-4/2019

2019-2021

prof. Ing. Hana Pačaiová, PhD.

Management of audits using a software application in accordance with the requirements of the ISO 9001: 2015 standard

Annotation (essence) of the scientific project: A labor market increases requirements for the new technologies day by day and with that a demand for changes in an education is closely connected. These two factors create a pressure on the level of knowledge for all the working positions. According to these changes, educational institutions keep adjusting actual and looking for new forms and methods of the education. Nowadays, the labor market, is mostly covered with producer organizations, which are focused on mechanical engineering and automotive industry. For this sector a management of all the processes is typical, where a management system is used based on the specific requirements of the ISO 9001:2015 standard. It is necessary to regularly review and improve the management system to apply the needed requirements. A tool for this review and improvement is an audit. Generally, preparation and implementation of the audit are time consuming and technically demanding processes. An effort of this project is to design a methodology to conduct the audits, which would make an audit process more effective and increase a reliability of assessed audit evidences supported by software application. The software application would be publicly available for acquiring skills in the education as well as a professional practice with a possibility to plan and conduct the audits.

VEGA 1/0121/18

2017-2020

Dr.h.c. mult. prof. Ing. Juraj Sinay, DrSc.

Development of methods for implementation and verification of a comprehensive security solution in Smart Factory as part of the Industry 4.0 Strategy.

Annotation (essence) of the scientific project: Industrial Revolution, known under the mark. INDUSTRY 4.0, brings new aspects affecting the relationship man - machine - environment. The increase in requirements for internal and external communication, individual approach, shortening the delivery time of a product or service requires the active participation of the organization but also the public in shaping the rules of human protection in the work environment in the system man-machine-work environment, ensuring safe operation and thus creating conditions for the protection of the interests (objectives) of Smart Factory. The output of the project will be the creation of a comprehensive database for identification and management of risks in the field of safety and health at work (Safety) and risks related to human activities in internal or external environment of intelligent organization (Security) integrated approach as part of the Internet of Things in the horizontal interconnected individual actors of production technologies, including logistics systems.

APVV-15-0351

2016-2020

Dr.h.c. mult. prof. Ing. Juraj Sinay, DrSc.

Development and application of risk management models in the conditions of technological systems in accordance with the strategy Industry 4.0.

Annotation (essence) of the scientific project: The Industry 4.0 strategy is based on the use of digitization of a part of production processes in industry so that the customer's requirements are taken into account. One of the strategic areas is security as part of the requirements for an efficient process of creating the final product. To implement this requirement, it is necessary to develop new procedures for the selection of characteristic parameters of risks so that they can be used in digital form for their mobility within the Internet. The aim will be the integrated processing of information on human and technical risks in their management system so that effective preventive measures can be applied with production process management centers in order to implement a risk minimization strategy. The developed models will be tested mainly on complex technologies within selected companies from the automotive industry, where the implementation of Industry Strategy 4.0 will be in the most developed state.

KEGA č. 049TUKE-4/2014

2014 - 2016

prof. Ing. Hana Pačaiová, PhD.

Creation of e-learning support for education in the bachelor's study program - Quality of Production.

Annotation (essence) of the scientific project:The project will focus on designing a new model of education based on the utilization of elearning support. The aim of the project will be to create comprehensive (and concentrated) course material substituting commonly used reading material related to the selected subject. The Bachelor’s degree students will be able to actively use the proposed course material available via a web application and the course contents will be divided into two coherent and independent modules.

Mastering a selected course will be verified by tests available via the web application. The project activities will include creating supplementary reading material.

APVV-0337-11

2012 - 2015

Dr.h..c. mult. prof. Ing.Juraj Sinay, DrSc.

Research into new and emerging risks of industrial technologies in the context of integrated security as a prerequisite for managing sustainable development.

Annotation (essence) of the scientific project: The effective process of management (management) of new and emerging risks of industrial technologies within integrated safety includes the safety of machines and technical systems, occupational safety - Safety and some categories of civil safety - Security. It depends on the forms and methods of relevant risk identification and quantification and subsequently on the appropriate ways of their management in the human - machine - environment system. By applying models to support the sustainable development of industrial technologies in a competitive environment on the basis of integrated risk analysis, taking into account specific threats in individual stages of the life cycle (RU) of technologies or. The final products of the product will create a mechanism that will allow the application of effective prevention methods. These procedures are used to take into account the development of new materials, new technologies, changes in the demographic development of the company as well as the application of powerful methods of ITC techniques and technologies. For effective feedback on the assessment of the resulting solutions, as more parametric systems, key performance indicators KPI - Key performance indicators will be developed and subsequently tested on specific types of industrial technologies.

VEGA 1/0107/12

2012 - 2014

Dr.h..c. mult. prof. Ing.Juraj Sinay, DrSc.

Research of the process of risk management of machines and technical systems at the interface Safety - safety of technical systems and work safety and Security - civil safety.

Annotation (essence) of the scientific project: Effective process of risk management within the safety of machines and technical systems, occupational safety - Safety in interaction with civil safety - Security, as one of the current priorities of the company is largely dependent on the relevance of risk identification and quantification and subsequentappropriate ways of controlling them in the man-machine-environment system.Given the common principles of risk management in Safety and Security, it is necessary to develop methods for the application of technical solutions, linked to the human factor, so that the dominant principle of risk minimization is preventive measures based on the use of modern ICT techniques, maintenance technologies, including methods of technical diagnostics.KPI (Key performance indicators) parameters will be proposed to assess the effectiveness of these measures.

ITMS: 26220220151

2011 - 2012

Prof. Ing. Hana Pačaiová, PhD.

Jelšava - Development of a joint research and development innovation center and its use in streamlining the heat treatment of raw materials

KBaKP activity: 3.1.Risks, quality and safety of developed technologies and systems

ITMS: 26220220063

2010 - 2012

Prof. Ing. Hana Pačaiová, PhD.

BIOMASS - New technologies for energy-environmental and economically efficient biomass recovery

KBaKP activity: 2.2 Risks, quality and safety of biomass thermal recovery processes

ITMS: 26220120060

2010 - 2013

Prof. Ing. Juraj Sinay, DrSc.

CENTER OF EXCELLENCE - Technical, Environmental and Human Risk Management Research Center for the Sustainable Development of Production and Products in Mechanical Engineering

KBaKP activity: 1.1 Development of the G-RAM model for managing the continuous development of engineering products in a competitive environment

ITMS: 26220220064

2010 - 2012

Prof. Ing. Juraj Sinay, DrSc.

VUKONZE - Research Center for the Efficiency of the Integration of Combined Renewable Energy Sources Systems

KBaKP activity: 2.5 Research on integrated risk life cycle management support for renewable energy sources

VEGA 1/0240/09

2009 - 2011

Dr.h..c. mult. prof. Ing.Juraj Sinay, DrSc.

Research of methods of integrated risk management systems of technical equipment and industrial technologies.

KEGA 3/7103/09

2009 - 2011

prof. Ing. Aurel Sloboda, PhD.

Application of theoretical knowledge in the construction of a prototype experimental vehicle with minimal fuel consumption in order to increase interest in mechanical engineering.

CP - IP 213345-2

2008 - 2013

Prof. Ing. Hana Pačaiová, PhD.

7.RP -iNTegRisk - Early Recognition, Monitoring, and Integrated Management of Emerging, New Technology related, Risks

Aktivita KBaKP:

T1.5.1 D1: Definition of KPIs emerging risks for selected industry case studies, including CSR aspects of emerging risks

T2.3.1 Gap analysis to identify missing models and methods within the iNTeg-Risk Framework

T2.4.1 Development of KPIs for Technology

T2.6.4 Guidance Topic D: Policies

T3.1.7 Case studies of Integrated Risk Management

KEGA č. 3/215604

2005 - 2007

prof. Ing. Juraj Sinay, DrSc.

Use of new multimedia technologies and materials in the teaching of case studies in the field of quality management systems.

VEGA č. 1/2217/05

2005 - 2007

prof.. Ing. Aurel Sloboda, PhD.

Research and implementation of an ecologically controlled four-stroke internal combustion engine with an output of up to 1000W with regard to minimizing fuel consumption with high functional reliability for the vehicle.

VEGA č. 1/2220/05

2005 - 2007

prof. Ing. Juraj Sinay, DrSc.

Research into methods for assessing the risks of major industrial accidents and their applications in risk assessment in industry.

VEGA č.1/ 9404/ 02

I.2002-XII.2004

Research of methods of implementation of acceptable risk of machinery in the stage of its design

Annotation (essence) of the scientific project: At the design and construction stage of machinery and technological systems, European Union (EU) directives as well as the laws of individual EU states prescribe the determination of acceptable risk values as a measure of selected types of threats, both in safety assessment and in assessment of its environmental effects. In order to meet these objectives, it is necessary to define the risks arising from the nature of the operation and maintenance of the machinery. Taking into account individual types of risks based on hazard characteristics in accordance with STN EN 292, methods are proposed to define the values of acceptable risks so that when quantifying it is possible to define the component that can be influenced during design and the component that can be controlled during machinery operation. At the design stage of the machine, procedures are designed to check compliance with the acceptable risk values so that the interaction between the main design software and the software controlling the acceptable risk values is possible. In the operation phase of the machinery, a maintenance strategy based on the theory of technical risk will be developed. The economic parameters of the maintenance activities will define its scope and thus the value of the acceptable risk in feedback to the requirements that need to be taken into account when designing the machine. Given that the human factor plays one of the essential roles in the field of technical risk management, its contribution to the determination of the final value of acceptable risk will therefore be addressed. To assess the correctness of the implementation of acceptable risk as a criterion for the safe construction of machinery, a system of audit procedures will be proposed in the mutual combination of project-machine construction-operating conditions.

VEGA č.1/ 6196/ 99

I.1999-XII.2001

Integrated quality management system and its application in the design of material flows and construction of machine systems using CA-techniques

Annotation of the original results of the project solution:

As part of the project solution, a system for integrating risk management (safety) tools and environmental management systems as part of quality management systems according to 900/2000 into the construction phase of machines and machine systems as part of material flows and partly also complex production technologies has been designed and is currently being tested. Risk management systems as well as environmental management have been applied to specific types of transport machinery, mobile and agricultural machinery.

Čo je výstupom štúdia na bakalárskom programe Kvalita a bezpečnosť

Absolvent študijného programu:

Ponúkame Ti

Naučíme Ťa:

Prečo študovať Bezpečnosť technických systémov

Ponúkame Ti

Naučíme Ťa:

Membership of department staff in cooperating organizations

prof. Ing. Hana Pačaiová, PhD.

prof. Ing.Milan Oravec, PhD.

Doc. Ing. Štefan Markulik, PhD.

Participácia KKBaE na Ulysseus Research Summite

V októbri 2023 sa dvaja členovia katedry KKBaE zúčastnili na medzinárodnej konferencii „Towards Innovations in Ageing and Well-Being (TINAW)“. Pozvané odborné prednášky boli účelovo vyberané tak, aby spojili výskumníkov, predstavili ich vedecký záber pre pracovné stretnutie HORIZON projekt „LIWE 2.0“.

Zhrnutie z aktivity nájdete tu.

CONTACT

TECHNICAL UNIVERSITY OF KOŠICE

Faculty of Mechanical Engineering

Institute of Special Engineering Processes

DEPARTMENT OF SAFETY AND QUALITY

Letná 1/9, 042 00, Košice - Sever

tel: +42155 / 602 2501

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.