- Details

LABORATORY OF PROSTHETICS AND ORTHOTICS

responsible person: Ing. Lucia Bednarčíková, PhD.

Location: Letná 9, main building, ground floor B-block, room B/P023

Focus of the laboratory

The laboratory is focused on diagnostic procedures and taking measurement data for the design and production of orthopedic aids. The laboratory's equipment is primarily used for postural and podiatric analyzes and the subsequent production of orthopedic insoles. Students can deepen and verify their theoretical knowledge in subjects such as Prosthetics and Orthotics I./II., Biomechanics in Prosthetics and Orthotics I./II. and Proteometry.

Objectives of the laboratory

- Gain knowledge about the possibilities and application of innovative technologies in the field of prosthetics, orthotics and calceotics.

- Familiarize students and teach them to work with equipment and methods used in practice by orthopedic technicians.

- To deepen students' theoretical knowledge and technical skills in the design, manufacture and application of orthoses.

|

|

DEVICE FOR ORTHOPEDIC INSOLS FORMING (SIDAS PODIATECH)

|

|

|

PODOSCOPE (SIDAS DUOCAM)

|

|

|

|

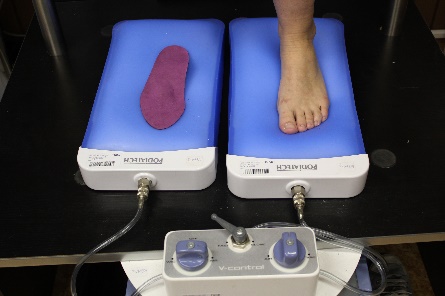

BAROPODOMETER (DIASU)

|

|

|

HEATING TUB (ORFIT) In the field of orthotics, the practical teaching focuses primarily on the production of orthoses from low-temperature thermoplastics, which are activated in water at a temperature of 60 to 70°C. |

|

|

BUILDING STAND FOR LOWER LIMB PROSTHESES In the field of prosthetics, it is a device for completing and determining construction lines and correctly aligning the components of modular prostheses of the lower limbs. |

Software

- DiaSu Milletrix - software for analysing the distribution of plantar pressure for Baropodometer

- Sidas DuoCam - software for foot diagnostic for Podoscope

Vyučované predmety

- Prosthetics and orhotics 1

- Prosthetics and orhotics 2

- Biomechanics in Prosthetics and orhotics 1

- Biomechanics inProsthetics and orhotics 2

- basics of Prosthetics and orhotics

- Protetometry

- Goniometry in Prosthetics and orhotics

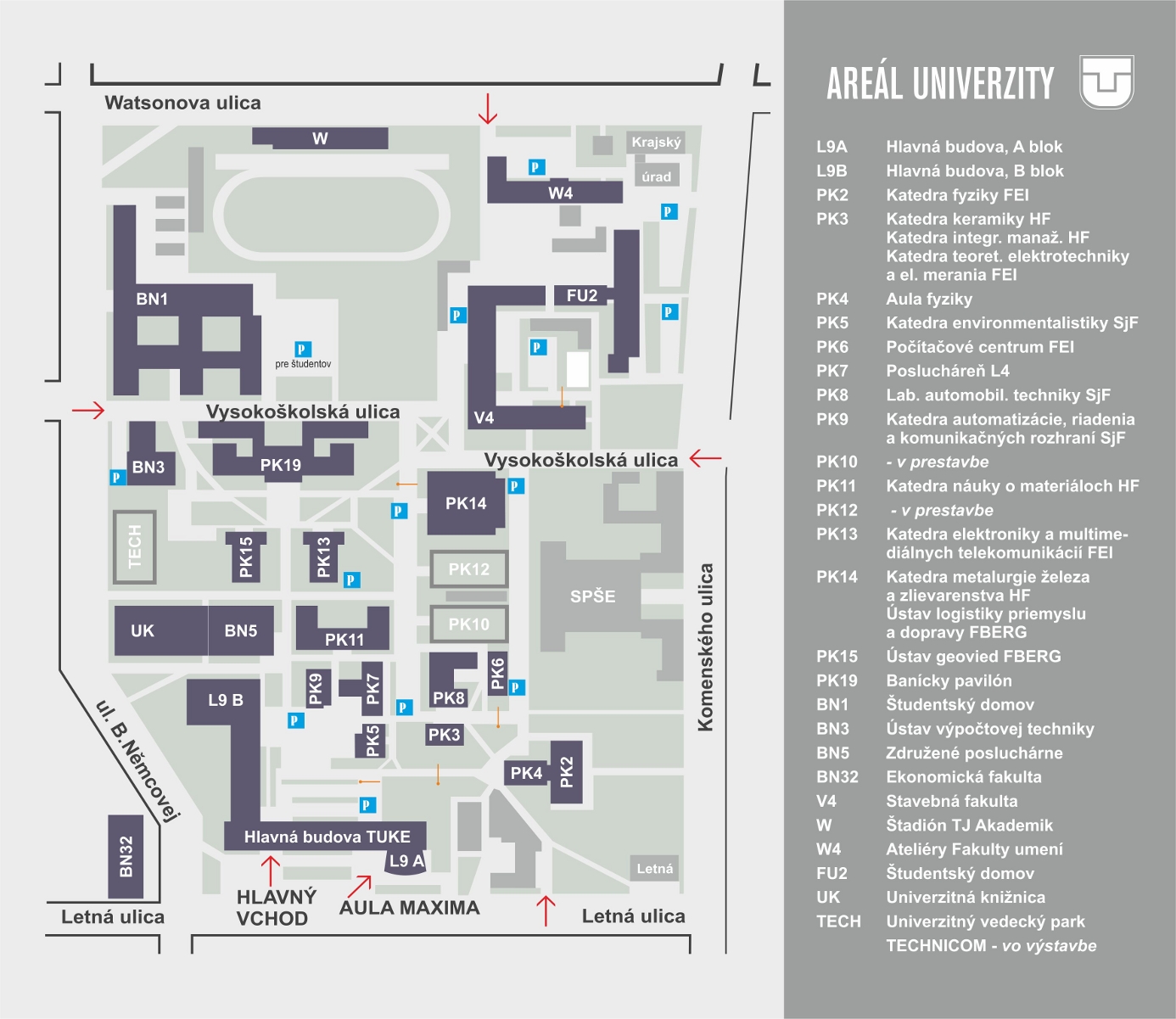

- Details

BIOMEDICAL ZONE - DIGITAL MODELLING AN SILMULATION LAB (BiZONE)

Responsible person: doc. Ing. Marek Schnitzer, PhD.

Location: Letná 9, main building, ground floor B-block, room P/B021

Focus of the laboratory

The laboratory will be primarily intended for teaching CAD modeling and simulation software with use in the field of biomedical engineering, measurement and prosthetics and orthotics.

The laboratory is currently closed due to renovation.

Design of BiZone LAB

- Details

LABORATORY OF ENGINEERING METROLOGY

Responsible person: Ing. Tatiana Kelemenová, PhD.

Location: Letná 9, main building, 3rd floor B-block, room B323

Focus of the laboratory

The laboratory is focused on the measurement of dimensions, geometric tolerances, electrical and non-electrical quantities in the field of mechanical engineering and electrical engineering. It is primarily used for teaching the subject of Mechanical Metrology for the entire 3rd year of bachelor's studies at the Faculty of Mechanical Engineering and for teaching other subjects that use measuring devices, sensors and gauges. It also serves for scientific-research activities in the field of measurement by teachers, scientific-researchers and students for the implementation of experiments related to final and diploma theses.

Objectives of the laboratory

- Zoznámiť To acquaint students with working gauges, sensors, precise mechanical and optical devices in the laboratory.

- Students will acquire theoretical as well as practical knowledge and skills in measuring length dimensions, surface quality,

- Gain parameters of machine parts such as threads or gears, but also for other quantities such as force, moment of force, pressure, temperature, humidity and electrical quantities.

- They will learn to use different measurement methods and to statistically process and evaluate measurement results..

Laboratory equpment

- working gauges, sensors and devices for measuring length and angle,

- instruments for measuring threads and gears,

- devices for measuring surface quality,

- devices for measuring force and moment of force,

- devices for measuring temperature,

- pressure, humidity, weight measuring devices,

- devices for measuring electrical quantities.

MEASURING MICROSCOPE MITUTOYO TM 176

- allows measuring dimensions and angles on small workpieces and for checking the shape of screws and gears

- digitalization of the microscope is possible by attaching a digital camera to the eyepiece tube kolies

ROUGHNESS MITUTOYO SURFTEST SJ – 210

- for contact roughness analysis according to EN ISO, VDA, ANSI, JIS standards

- measuring range 0,3 – 16 mm

INFRARED CAMERA FLIR E5

- contactless temperature measurements from -20°C to +400°C

- display of temperature fields of temperature distribution in the monitored space

CALIBRATION DEVICE FOR VERIFICATION OF MANOMETERS ADDITEL ADT914 + 681

It serves for the verification of manometers in the range up to 100 MPa

Software

- Q DAS Procella - statistical software for collecting and analyzing data from digital gauges

Taught subjects

- Engineering metrology (3rd year of bachelor degree)

- Details

LABORATORY OF CAD/CAM SYSTEMS

Responsible person: doc. Ing. Teodor Tóth, PhD.

Location: Letná 9, main bulding, 3rd floor B-block, č.m. B321

Focus of the laboratory

The CAD/CAM laboratory is moving to new premises in the BiZONE laboratory (ground floor B/P021).

- Details

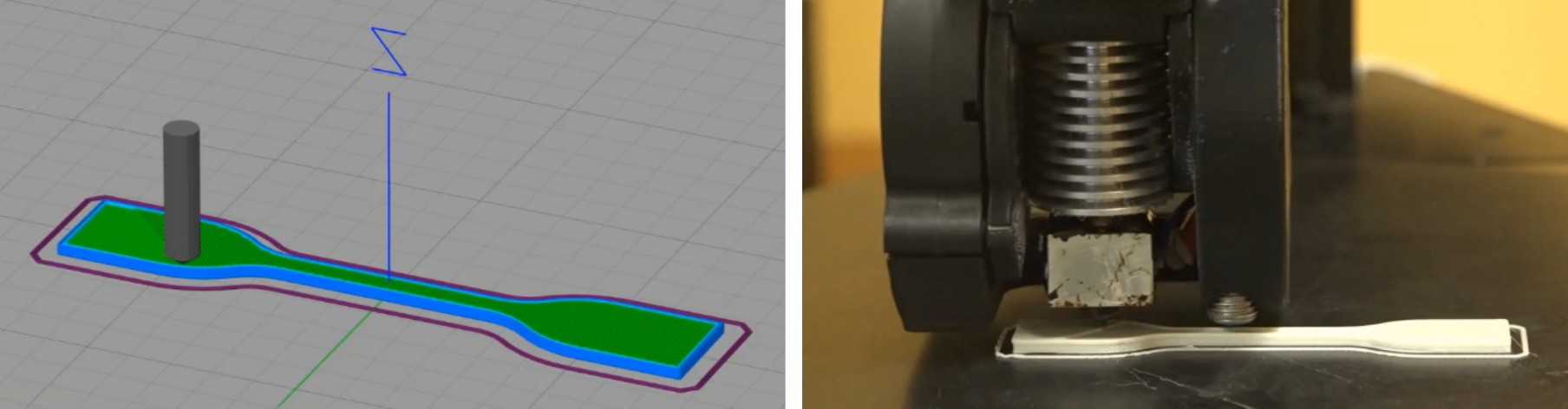

MEDICAL ADDITIVE MANUFACTURING UTILITIES LABORATORY (MAMUT 2)

Responsible person: doc. Ing. Marek Schnitzer, PhD.

Location: Letná 9, main building, ground floor B-block, room B/P026

Focus of the laboratory

The MAMUT 2 laboratory is focused on the production of filaments from low-temperature polymers (e.g. PCL ...) as well as the production of filaments from high-temperature polymers (e.g. PEEK, PPSU ....). Part of the production process is also the recording of the diameter of the filament, where it is possible to analyze this kind of parameter from the point of view of the quality of the produced filament. Students can thus verify theoretical knowledge in the field of production technologies in the form of produced filament. Another area of interest of the given laboratory is the filament recycling process, where it is possible to analyze the recycling process in terms of the production parameters of re-extrusion of filaments.

The output itself in the form of the manufactured filament can be further investigated in the 3D printing process using FDM technology. By setting and optimizing the required parameters in the pre-processing of 3D printing for a new type of material, students and employees of this workplace acquire knowledge in software and hardware solutions to the given problem. The output in the given area are experimental samples or models, which are further subjected to mechanical or biological testing.

.

Objectivs of the laboratory

- Production process of filaments from single-component and multi-component polymers intended for medical applications

- Evaluation of parameters and their influence on the filament production process itself

- Setup and optimization of the 3D printing process for multicomponent polymers intended for medical applications

- Analysis and evaluation of the quality of the manufactured filament Recycling of filaments and their reuse in the production process

- Expansion of students' theoretical and practical knowledge in the field of FDM technology and filament extrusion process aplikácie

Laboratory equipment

- Filament Maker „Composer series 450“ (3devo ; Holandsko)

- Filament Maker „Precision series 450“ (3devo ; Holandsko)

- Polymer dryer „Airid“ (3devo ; Holandsko)

- Polymer dryer „F300“ (Apium, Nemecko)

- Hybrid polymer shredder „GP20“ (3devo ; Holandsko)

- 3D printer „DeltiQ2“ (Trilab, Česká republika)

- 3D printer „DeltiQ2 Plus“ (Trilab, Česká republika)

- Palette2 S

Software

- Dassault Systemes SolidWorks

- Autodesk Fusion 360

- Simplify3D

- KISSlicer

- DevoVision

Taught subjects

- Digital modelling in medicine 1 (BE, Ing)

- Digital modelling in medicine 2 (BE, Ing)

- Biomedical engineering (BE, Ing)

- Biomechanisms (BE, Ing)

Technical university of Kosice

Faculty of mechanical engineering

Department of biomedical engineering and measurement

Letná 9, 5th floor A-block

042 00 Košice, Slovakia

Office hours:

Tuesday: 8:00 a.m to 12:00 a.m

Thursday: 8:00 a.m to 12:00 a.m