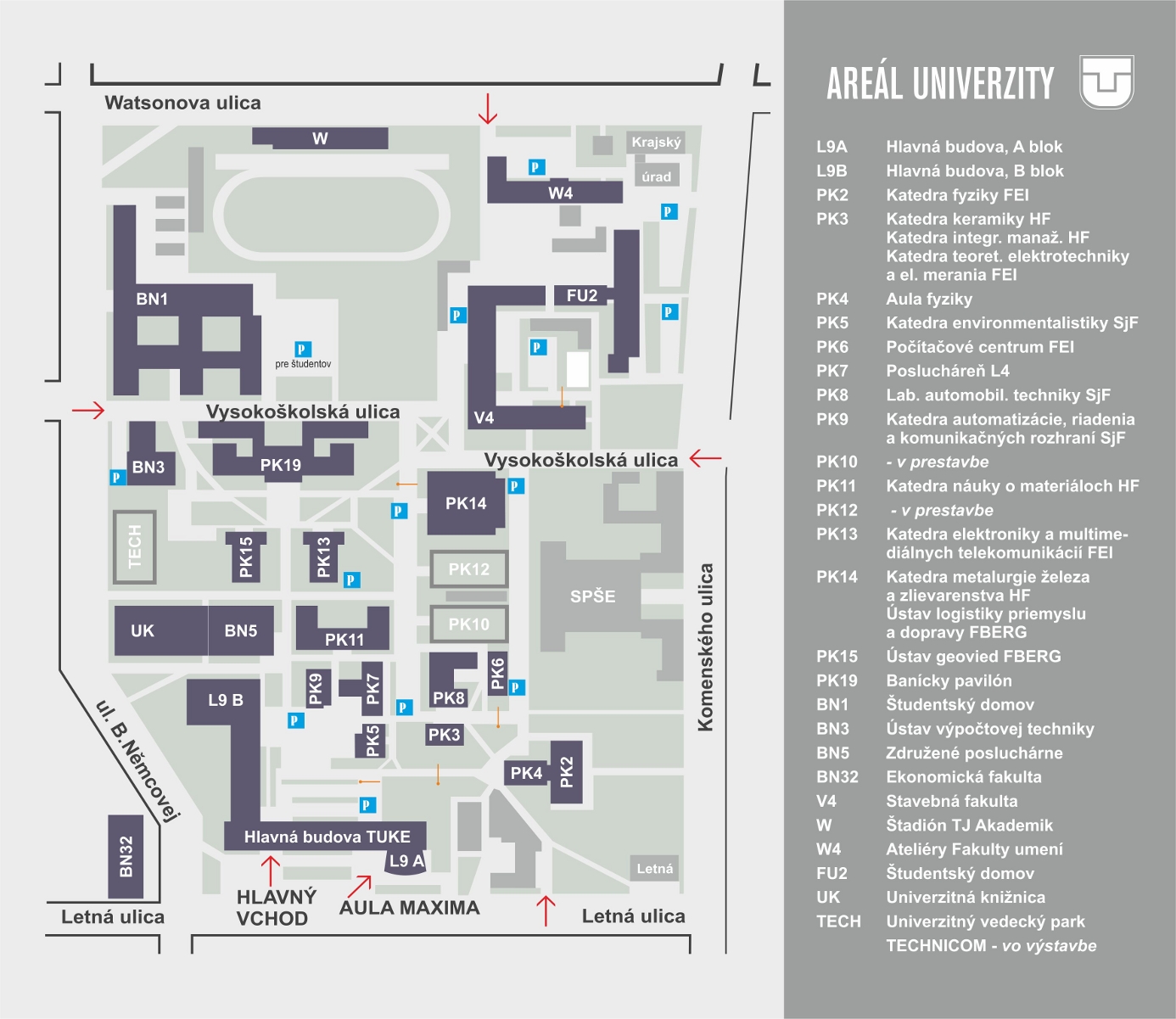

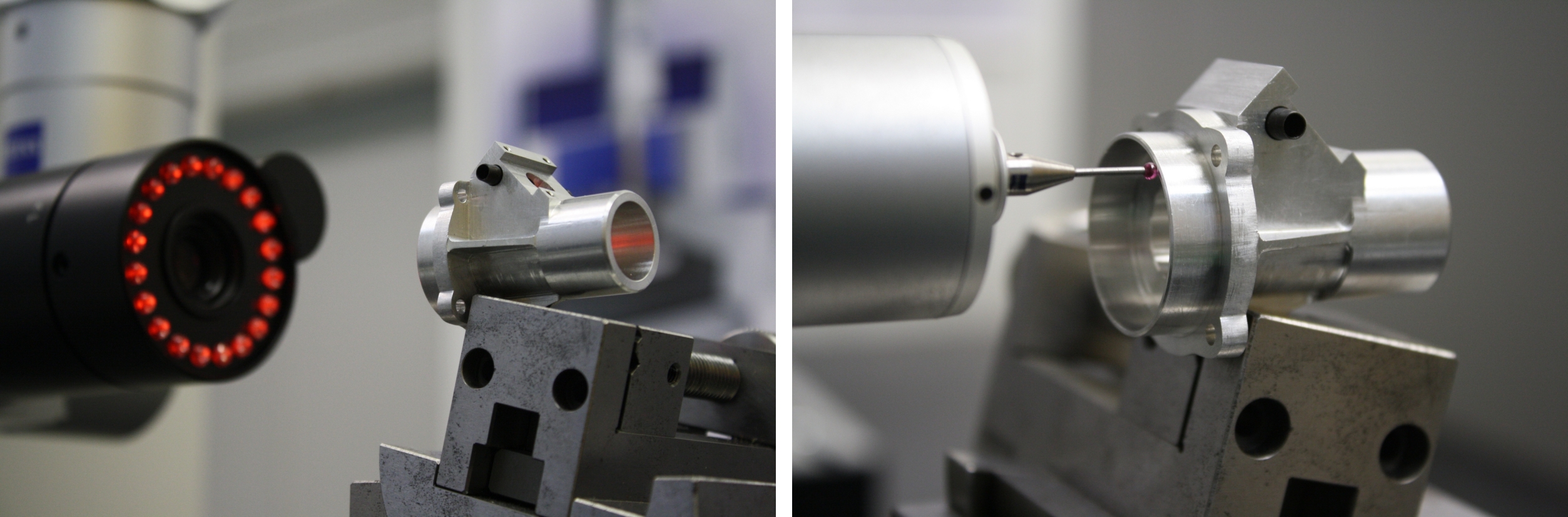

LABORATORY OF COORDINATE METROLOGY

Responsible person: doc. Ing. Teodor Tóth, PhD.

location: Letná 9, main building, ground floor B-block, room. B/P012

Focus of laboratory

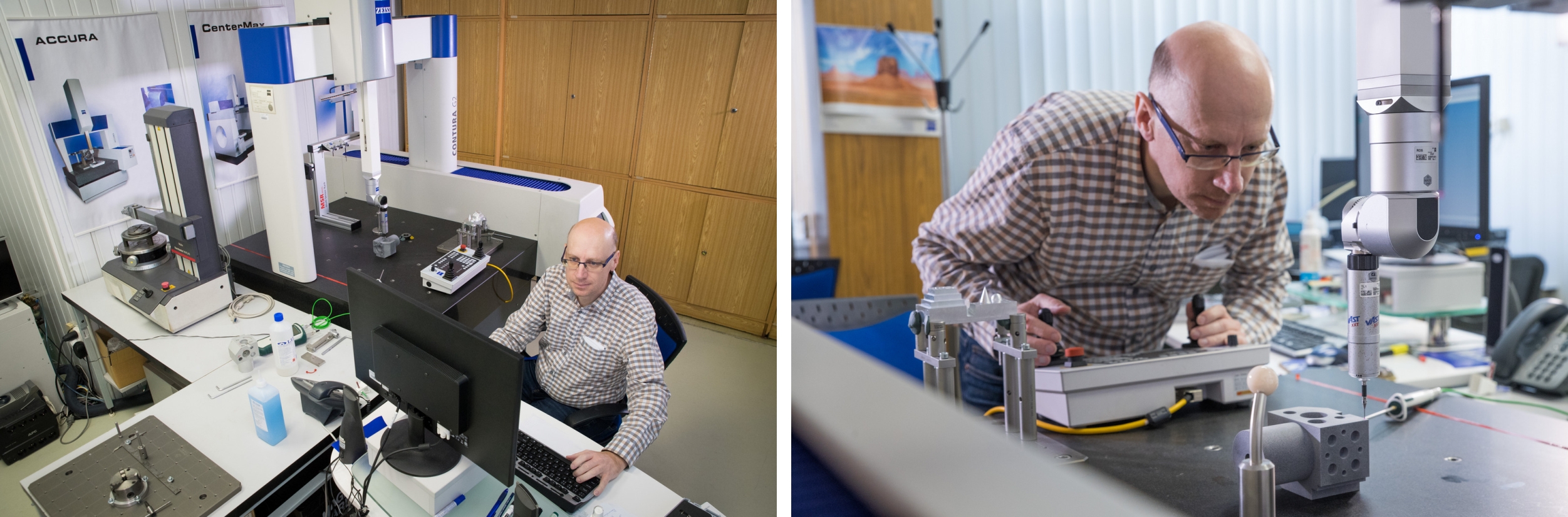

Coordinate measuring machines enable touch and non-touch assessment of the accuracy and quality of component production. the Contura G2 CMM is a gantry type for high-speed scanning. It is designed for measuring specific elements, in a number of positions with different angles and for small sensor configurations. The rotating Zeiss RDS measuring head allows measurement in 20736 positions and rotates in 2.5° increments, and with the support of Vast XXT technology it can scan in all positions. Computer-Aided Accuracy (CAA) technology ensures correction of kinematic deviations to achieve extremely accurate results.

Calypso evaluation and service software, based on CAD technology, enables object-oriented creation of CNC measurement programs. Fast and accurate scanning of known geometric shapes (circles, cylinders, cones, planes, ...) is ideal for efficient measurement of parts with a large number of tolerated parameters. Scanning known profiles (contours) of curves and general surfaces, as well as unknown curves, is ideal for digitization in tool and mold manufacturing. The HOLOS and GEAR superstructures are used to measure general surfaces and gears.

With the help of a coordinate measuring machine, it is possible to check the dimensions, shape and positional deviations of the parts.

Objectives of the laboratory

- To gain knowledge about the possibilities and application of coordinate measuring machines in the field of measurement

- Familiarize students and teach them how to create programs in Calypso

- Cooperation with universities on joint projects

- Cooperation with companies in solving production problems

Laboratory equipments

- Coordinate measuring machine Carl Zeiss Contura G2 - is a portal type for high-speed scanning. It is designed for measuring specific elements, in a number of positions with different angles and for small sensor configurations. The machine is equipped with an RDS rotating head and a VAST XXT scanning system or a ViSCAN optical system.

- Microscope Carl Zeiss Stemi DV4 SPOT with a camera for connecting to a PC - enables visual inspection and measurement

Software used in laboratory

- Carl Zeiss Calypso - Evaluation and service software Calypso, based on CAD technology, enables object-oriented creation of CNC measurement programs. The HOLOS and GEAR superstructures are used to measure general surfaces and gears.

- Carl Zeiss Zen - software for microscope

- Dassault Systeme Solidworks - CAD/CAM software

Vyučované predmety

- Engineering metrology (3rd year of Bachelor degree)