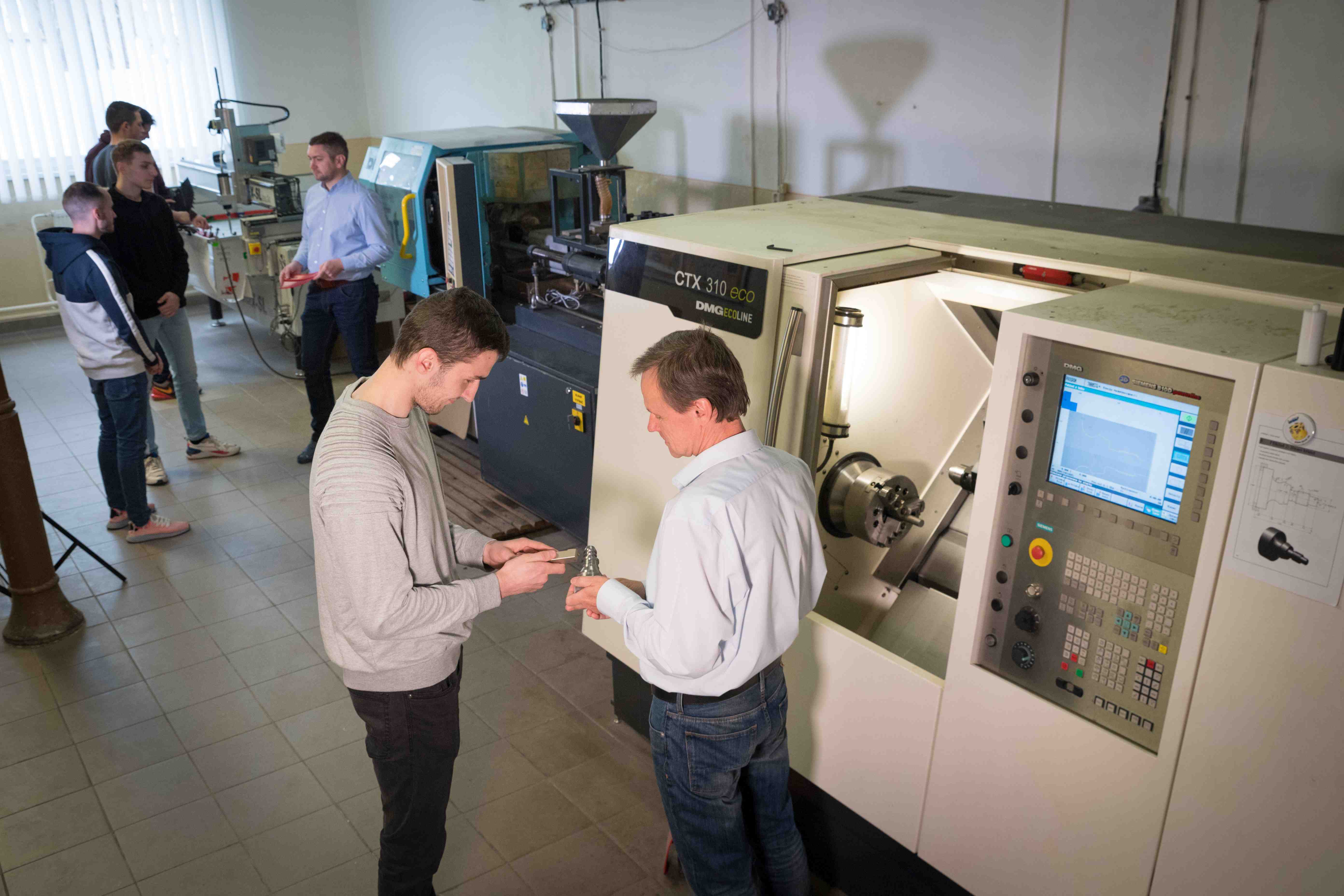

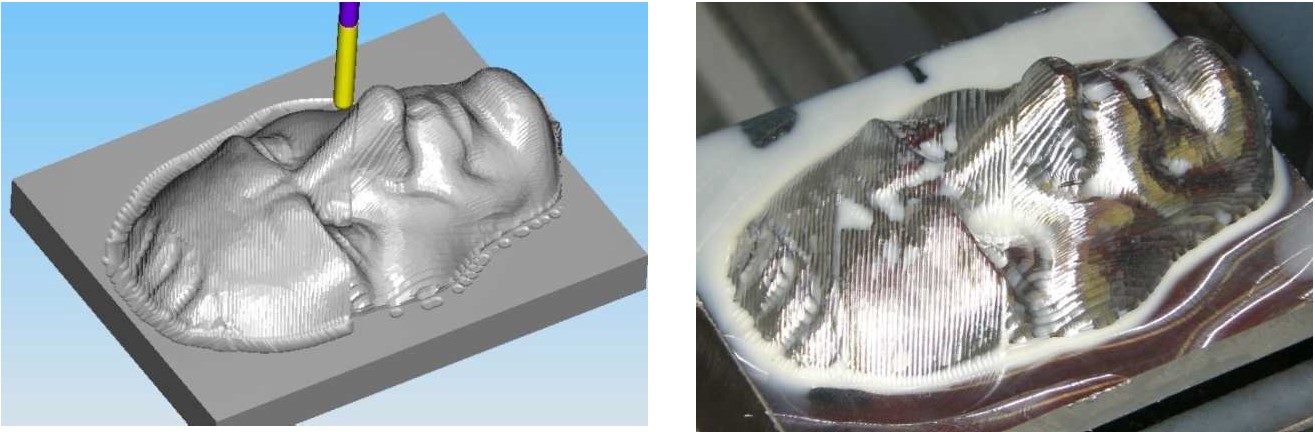

Laboratory of production programming on CNC machines

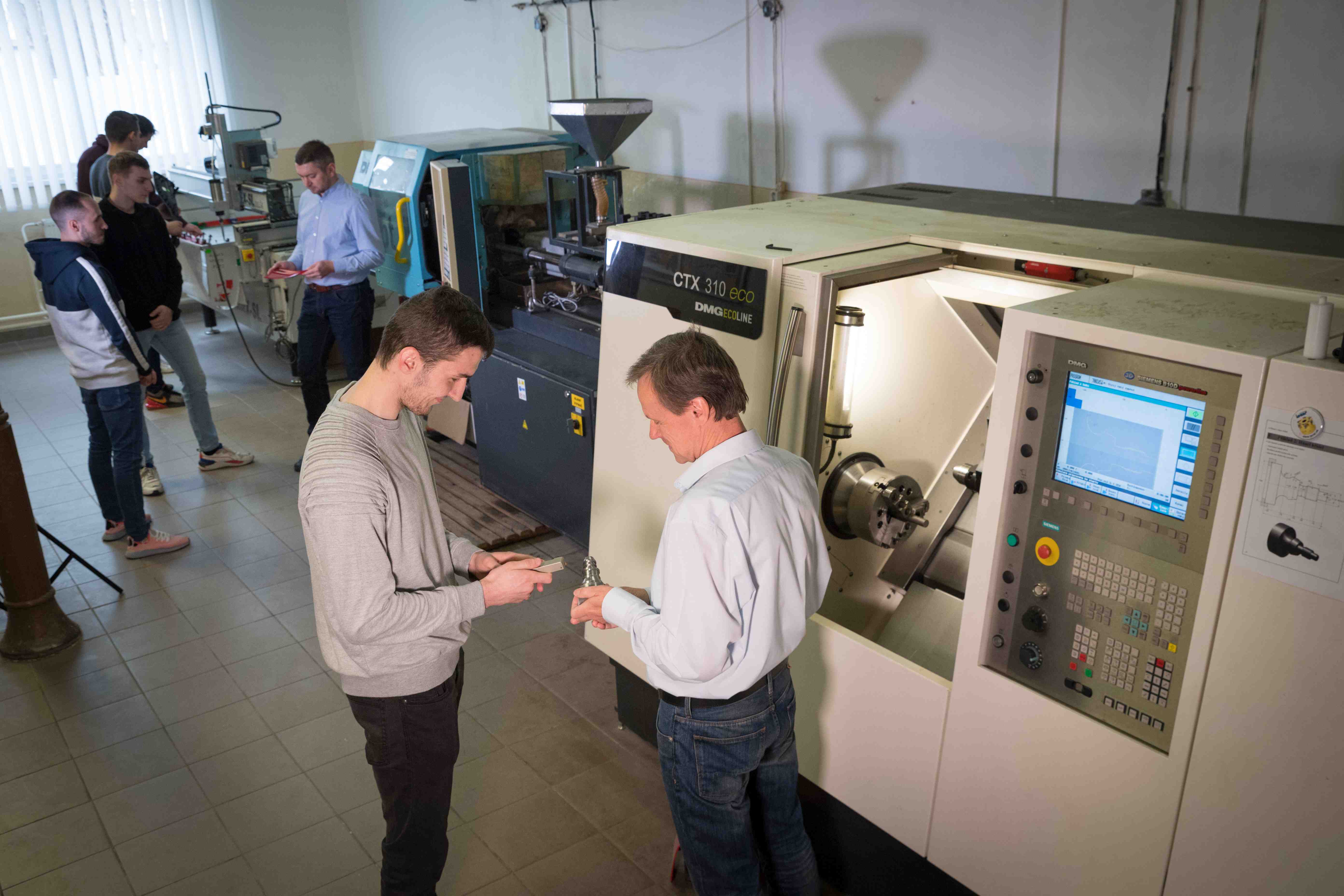

Laboratory of production programming on CNC machines (M74-040/A)

Responsible person: Ing. Ján Varga, PhD.

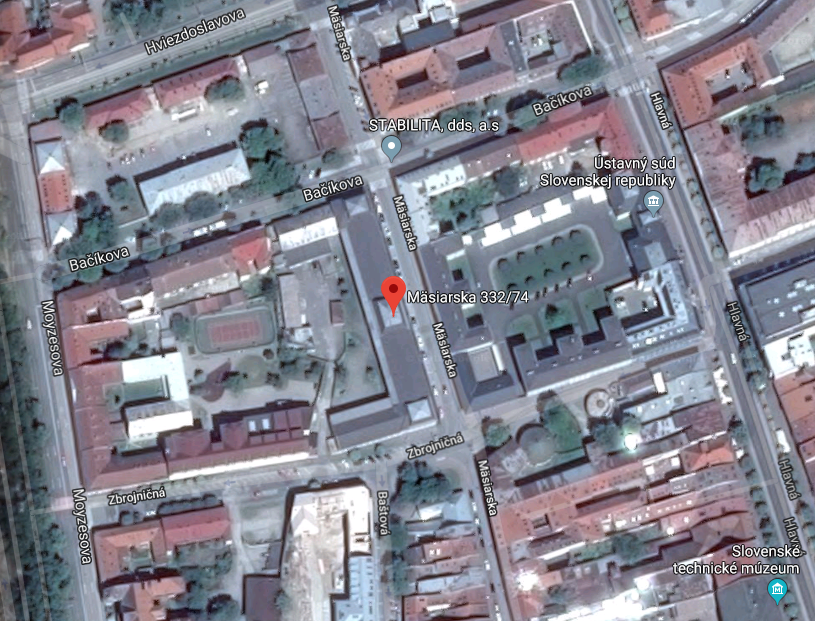

Location: Mäsiarska 74

Focus of the laboratory

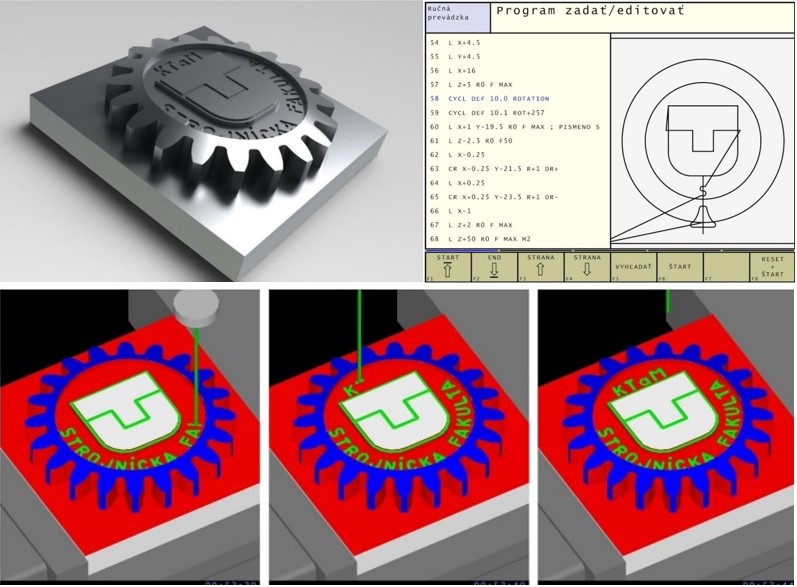

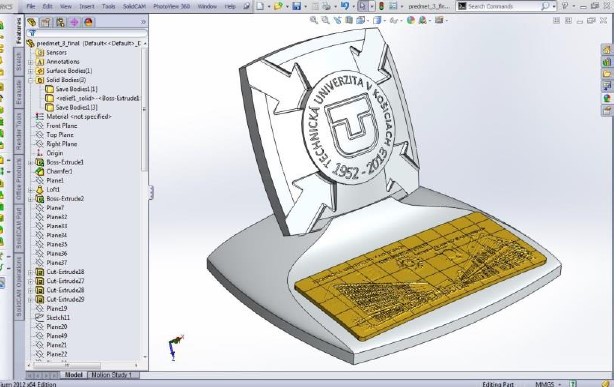

The laboratory is focused on teaching production programming on CNC machine tools. At present, the laboratory has equipment that is used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and doctoral theses at the department. The professional focus of the laboratory is the teaching of CNC machine tool programming.

Laboratory equipment

CNC milling machine EMCO concept Mill 155, programming consoles EMCO with panels for control systems Heidenhaim TNC 460 and Sinumerik 840D, CNC lathe DMG CTX 310 eco. Computer technology: PC with software for programming NC machines with CAD/CAM systems.

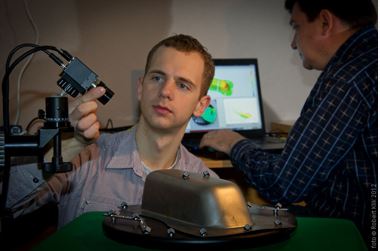

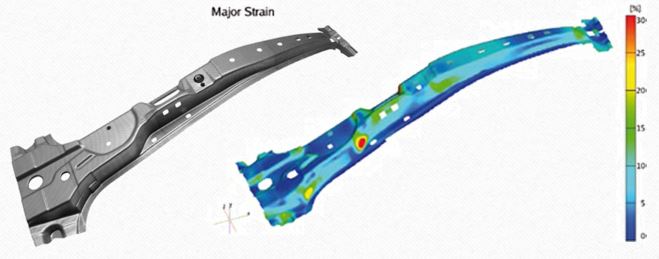

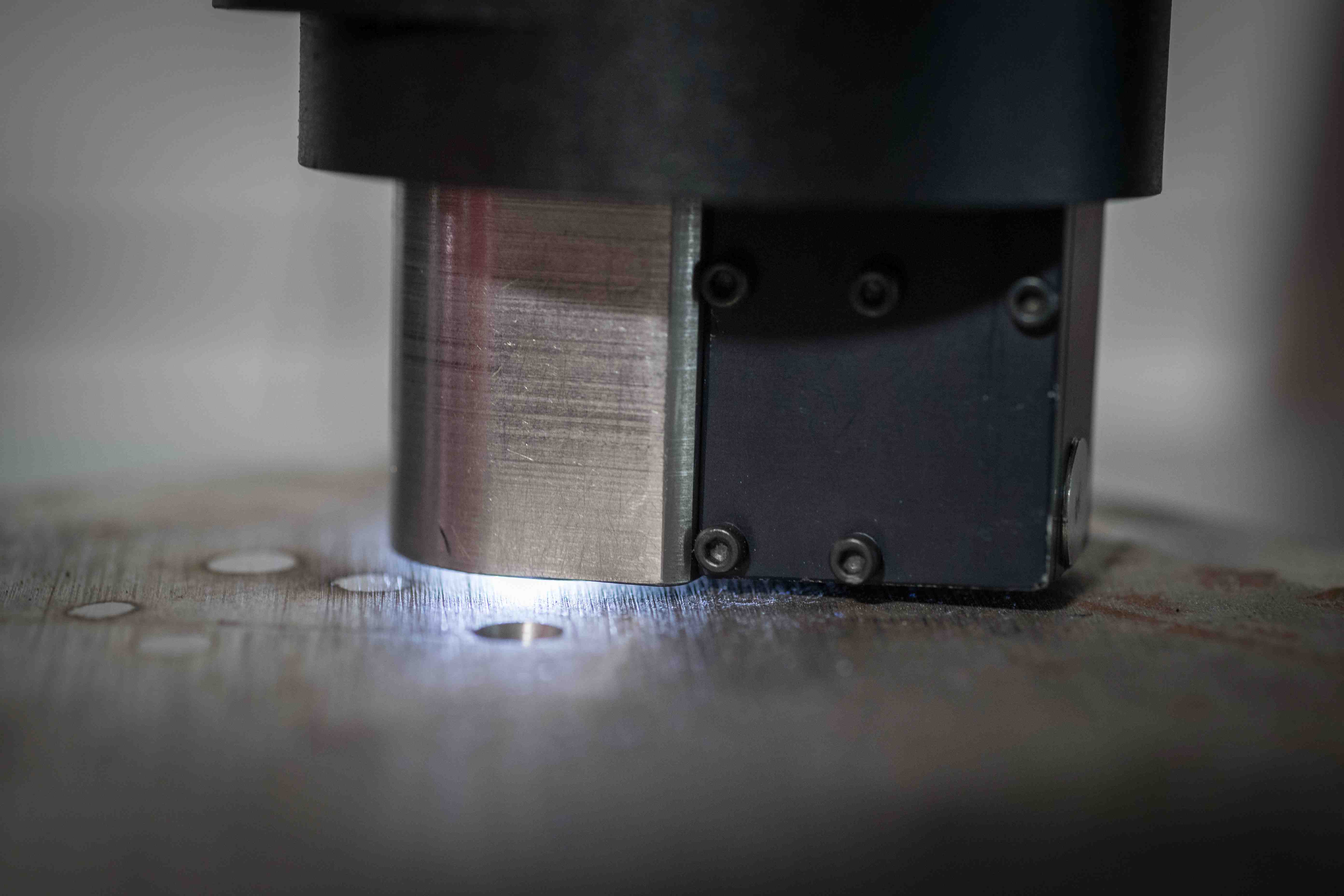

3D optical deformation measurement laboratory

3D optical deformation measurement laboratory (M74-108)

Responsible persons: prof. Ing. Ján Slota, PhD., Ing. Tomáš Jezný, PhD.

Location: Mäsiarska 74

Focus of the laboratory

The laboratory is used for non-contact measurement of 3D deformation on real parts. Currently, the laboratory houses equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor, master and doctoral theses in the department. The professional focus of the laboratory is modelling and simulation of forming processes and optimisation of technological processes.

Laboratory equipment

ARGUS 3D optical system for measuring deformations after forming and a powerful workstation for analysis of the results.

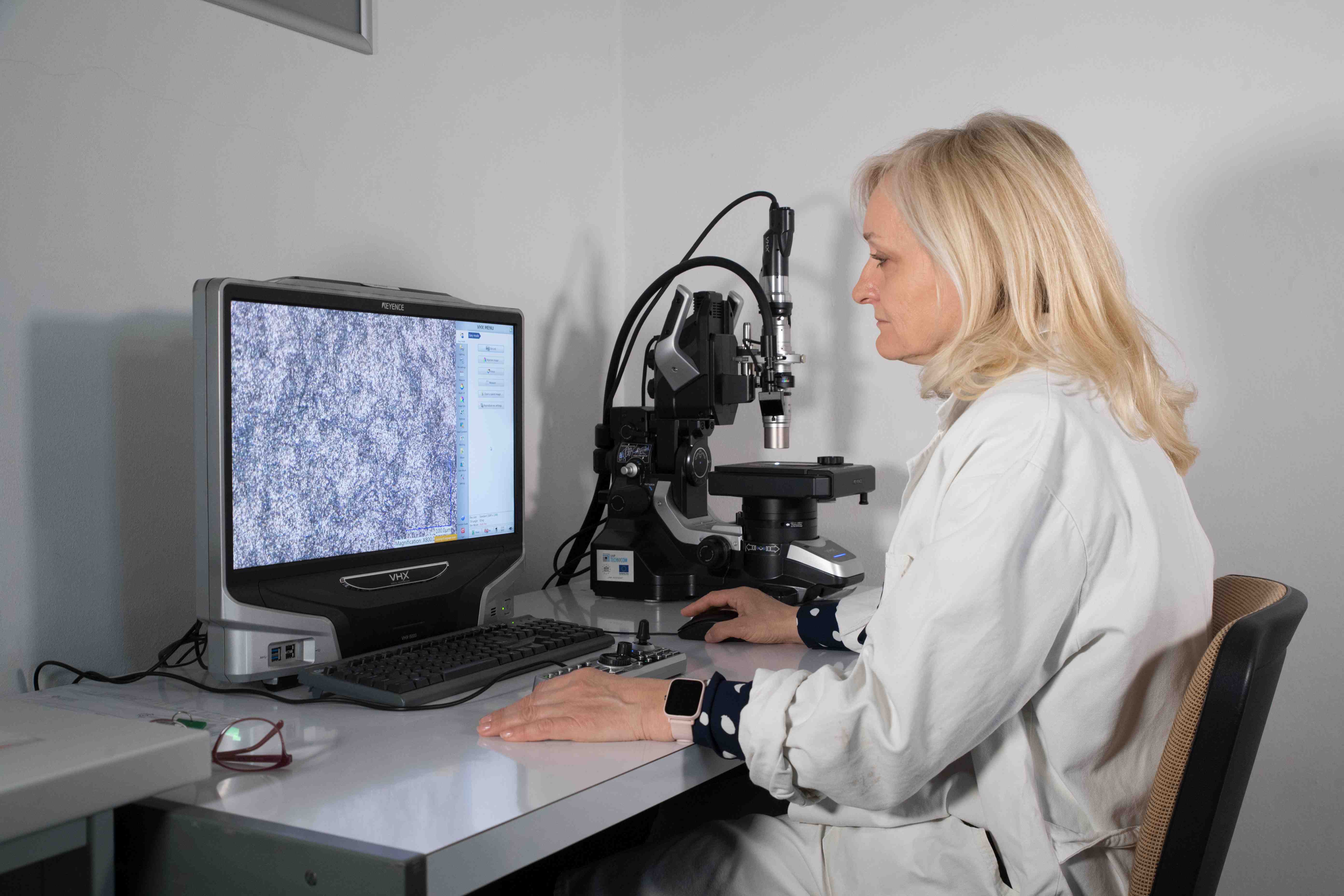

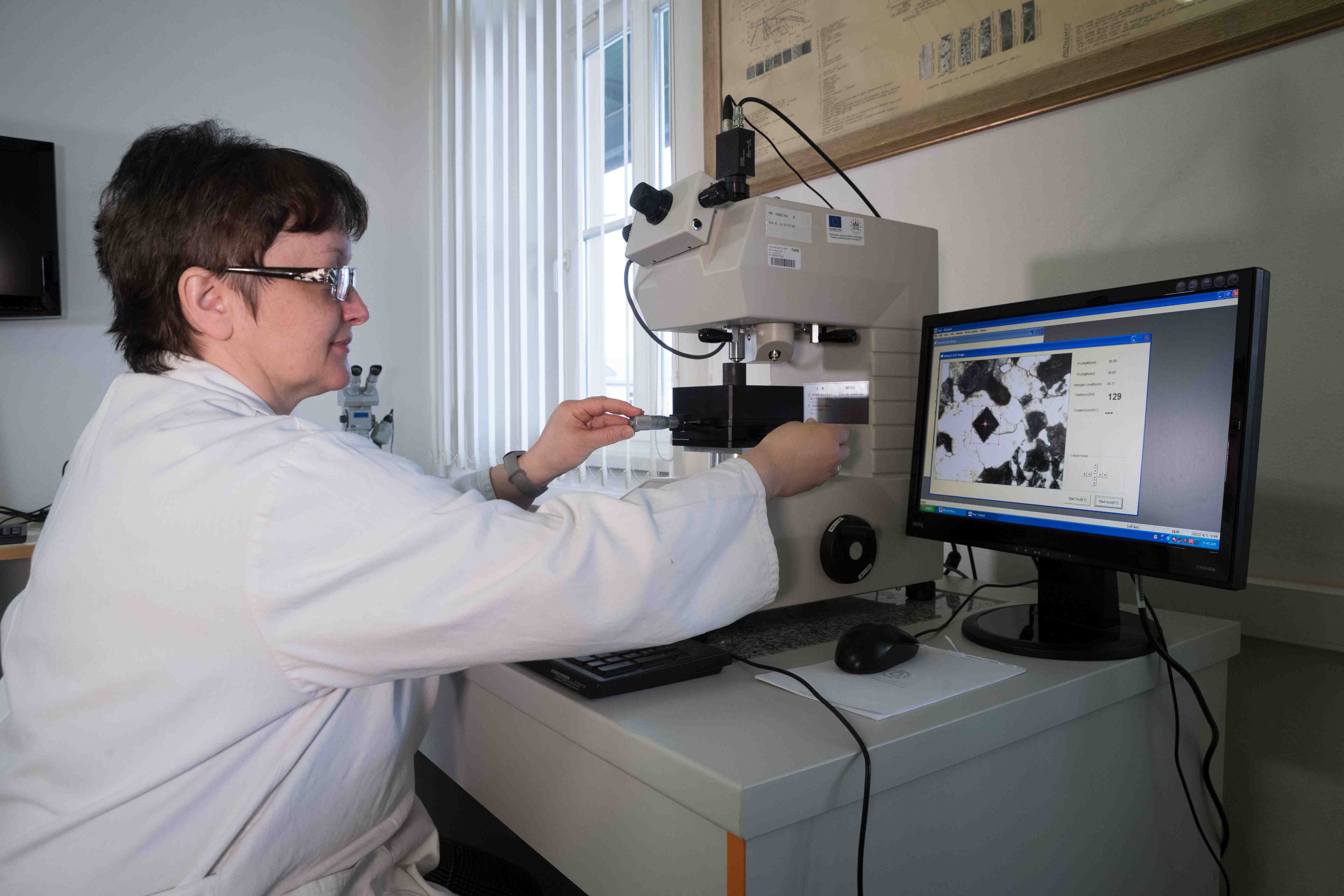

Light microscopy and metallography laboratory

Light microscopy and metallography laboratory (M74-155)

Responsible persons: doc. Ing. Anna Guzanová, PhD., doc. Ing. Ľuboš Kaščák, PhD.

Location: Mäsiarska 74

Focus of the laboratory

The laboratory focuses on metallographic study and documentation of macro and microstructures of metallic and non-metallic materials, layers and coatings, determination of corrosion characteristics of base materials, evaluation of corrosion efficiency of layers and coatings, measurement of microhardness of materials, analysis of fracture surfaces and topography of surfaces. The laboratory also houses equipment used for scientific and research activities in basic and applied research, as well as for the solution of final bachelor's, master's and doctoral theses.

Laboratory equipment

Metallographic grinder and polisher Struers Tegramin - 20, chemical digester ALK 697, ultrasonic cleaner, mechanical grinder - polisher Buehler, condensing chamber Liebisch Constanzo KBEA 300, condensing chamber KK 320, digital microscope keyence VHX - 500, Neophot-2 light microscope, Olympus metallographic microscope BXFM, Carl Zeiss Epityp 2 microscope, BK 70x50 microscope, Belec Compact Port mobile spectrometer, BioLogic SP-150 device for measuring electrochemical characteristics of surfaces.

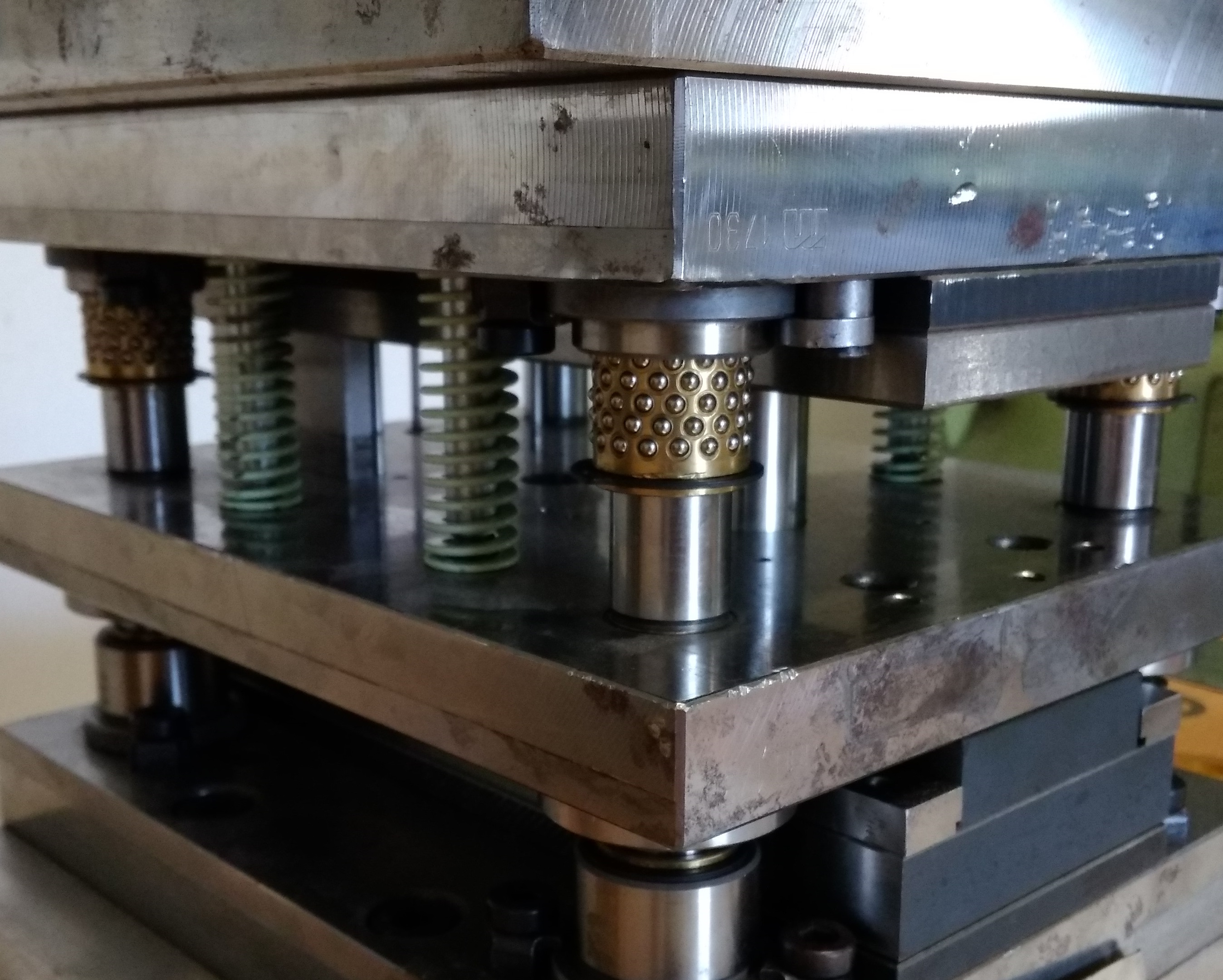

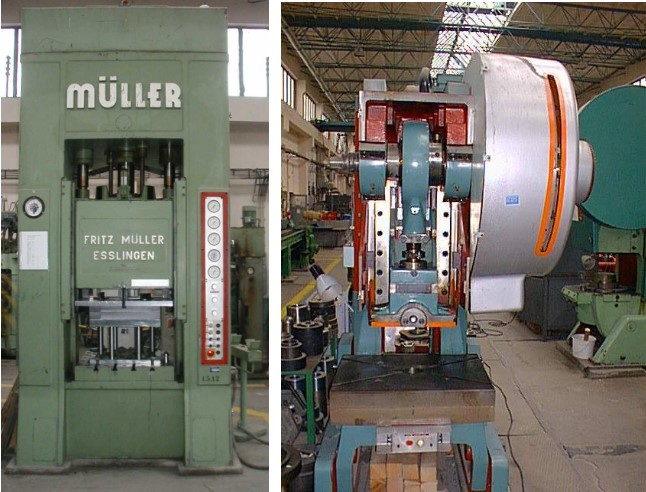

Forming laboratory

Forming Laboratory

Responsible person: doc. Ing. Janka Majerníková, PhD.

Location: Mäsiarska 74

Focus of the laboratory

The laboratory is focused on experimental verification of designed forming technologies on the principle of physical modelling and verification of the functionality of manufactured forming tools by making real mouldings. Currently, the laboratory houses equipment used for scientific and research activities of basic and applied research. The equipment is also used in the solution of bachelor, diploma and dissertation theses at the department and in the teaching of the programmes Technology, Management and Innovation of Engineering Production, Engineering Technology and Computer Support of Engineering Production. Laboratory expertise: testing of complex formability of newly developed steel sheets.

Laboratory equipment

LE 4 eccentric press, Compact 60 hydraulic shears, TTA 12/12 bending machine, progressive shearing tool, equipment for the suspension test of thin plates, equipment for the production of test specimens for the suspension test.

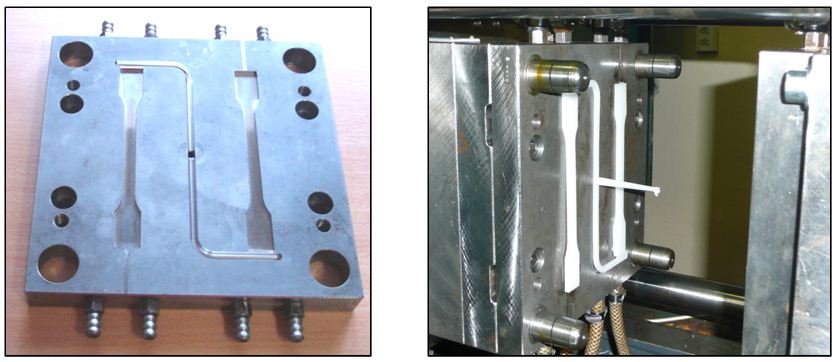

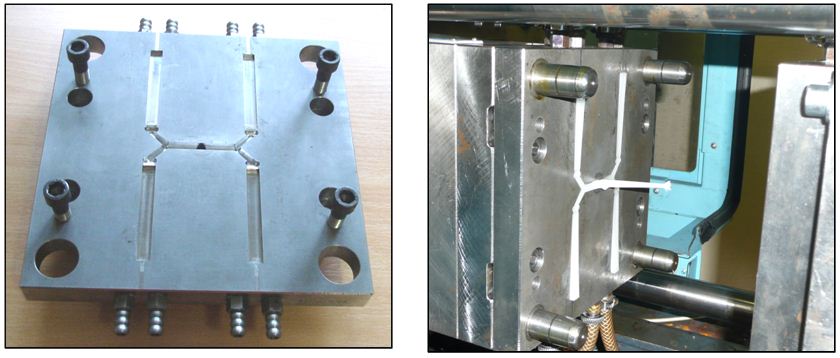

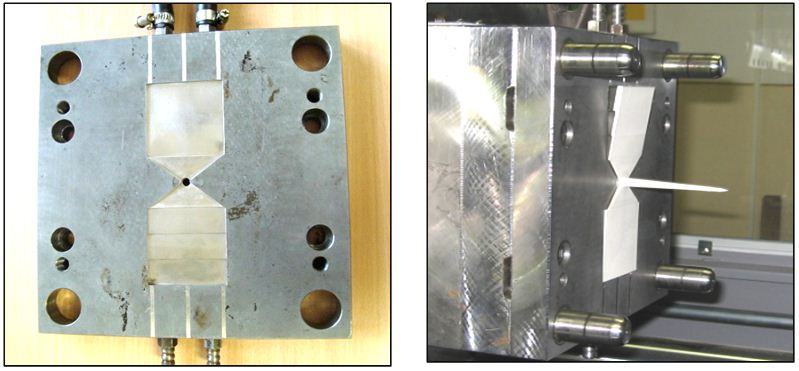

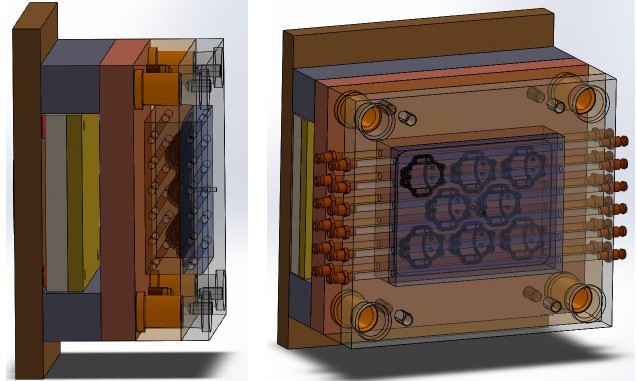

Plastics Processing Laboratory

Plastics Processing Laboratory (M74-026)

Responsible persons: doc. Ing. Ľudmila Dulebová, PhD., doc. Ing. Ivan Gajdoš, PhD.

Location: Mäsiarska 74

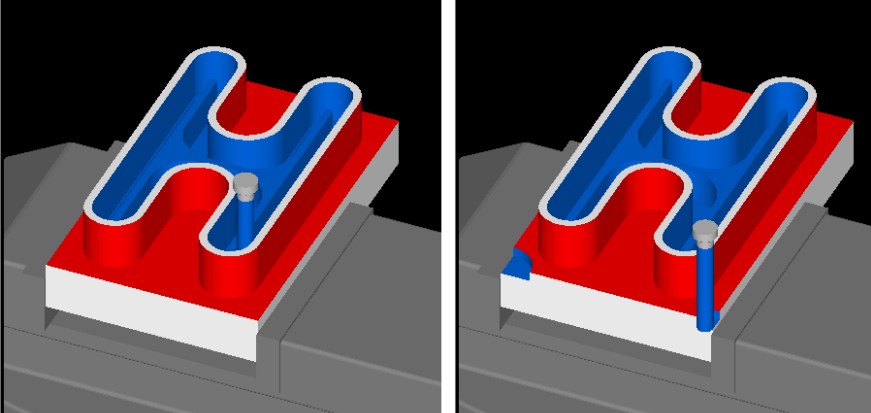

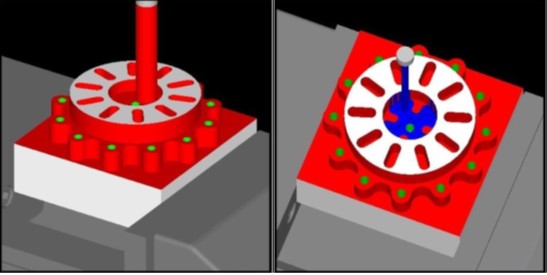

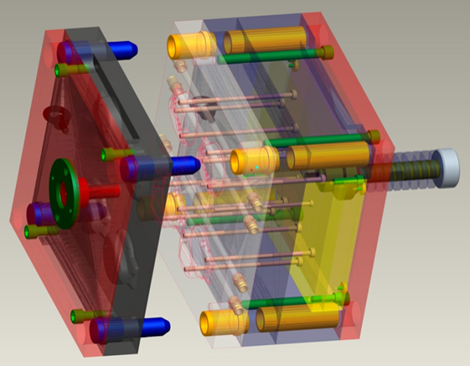

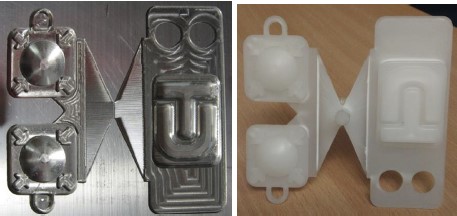

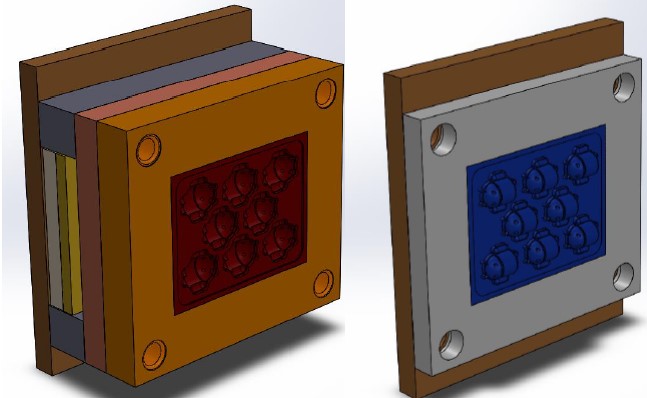

Focus of the laboratory

The laboratory focuses on the verification of mould functionality, moulding and testing of plastic mouldings. At present, the laboratory contains equipment that is used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and doctoral theses at the department. The professional focus of the laboratory is the detection of the mechanical properties of plastics and the manufacturability of the production of moulded parts.

Laboratory equipment

Demag plastic injection moulding machine, Shore hardness testers (A, D), Charpy hammer, recycling mill for grinding plastic waste, Raman spectrometer, Moldex3D - software for simulation of plastic flow into moulds, SolidWorks, PTC Creo + DME Digital product catalogue + HASCO catalogue (software for designing plastic parts and moulds for their moulding).

tensile test impact toughness test hardness test