Responsible person: prof. Ing. Peter Trebuňa, PhD.

Location: Komenského Park 9, 1 floor, no. d. 103

Workplace focus

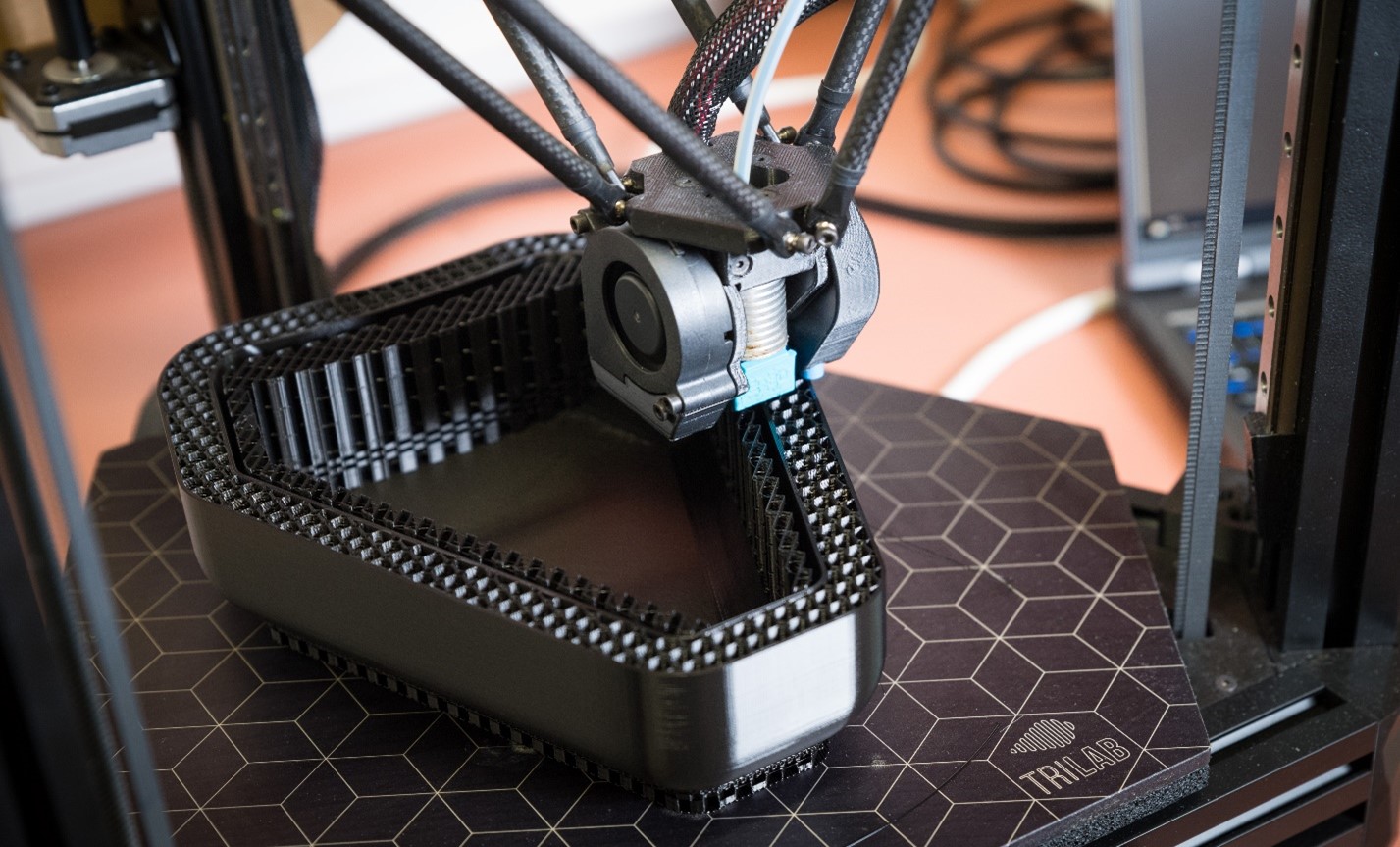

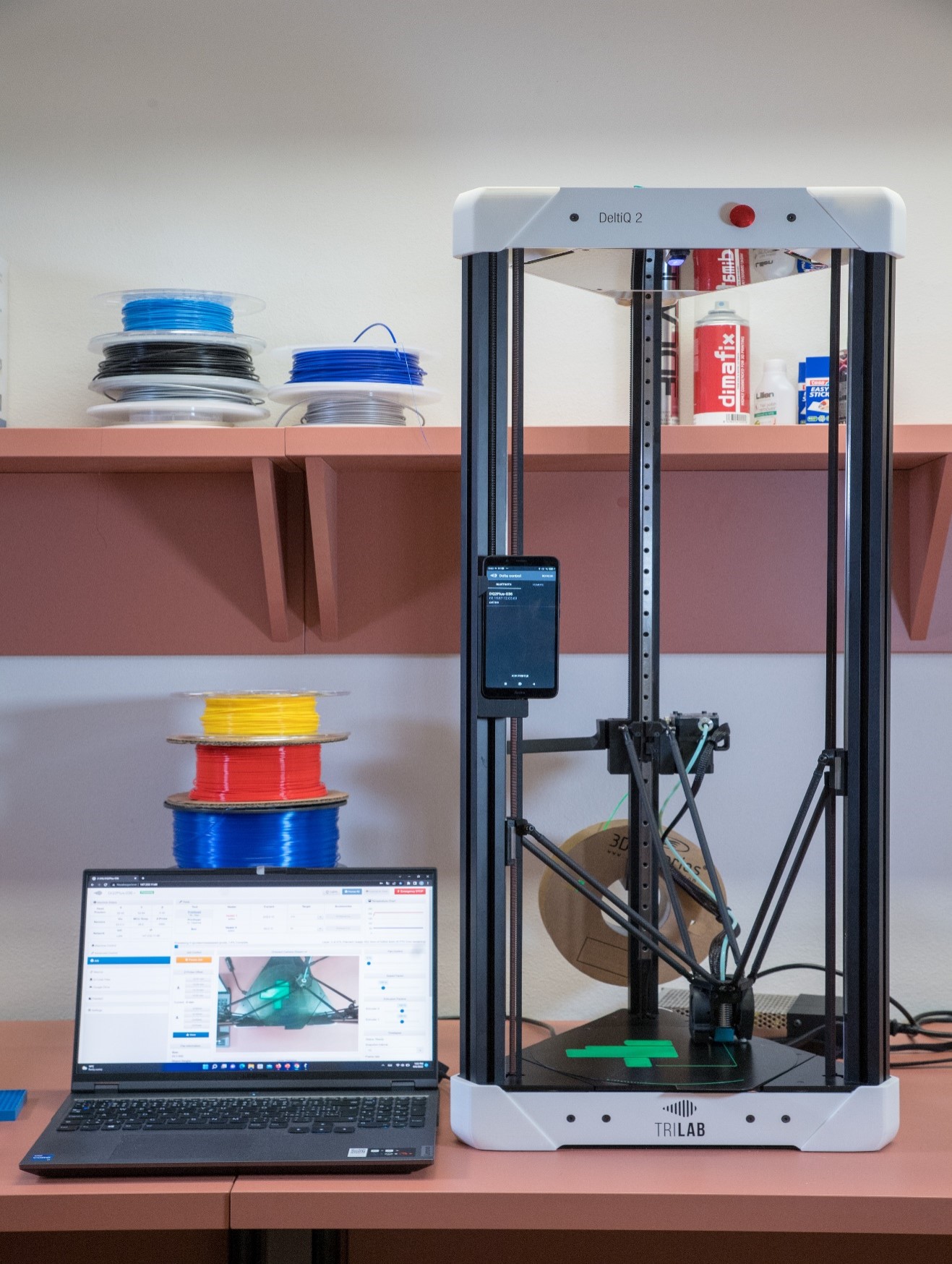

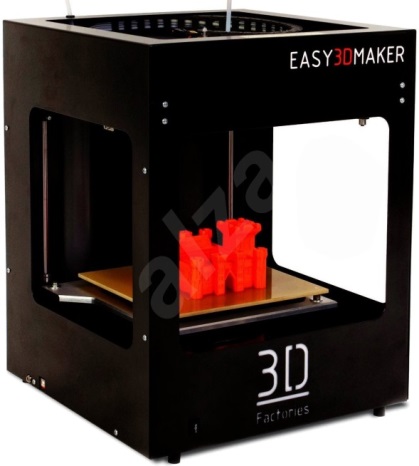

In the workplace of additive technologies, the teaching of the 3D printing process is carried out. Undergraduate and engineering students learn how to create models, edit a model in KISSlicer, export to a printer, and how to start and stop 3D printing. Prototypes and models for bachelor's and master's theses are printed at the workplace of additive technologies.

Workplace goals:

- 3D printing.

Laboratory equipment:

- 1x 3D printer Trilab Deltiq XL,

- 1x 3D printer Trilab Deltig 2 plus,

- 1x 3D printer Ultimaker 3,

- 1x 3D printer ZMorph

- 2x 3D printer Easy 3D Maker

Subjects:

- Laboratory training,

- Thesis,

- Term project,

- Creating models for simulation.

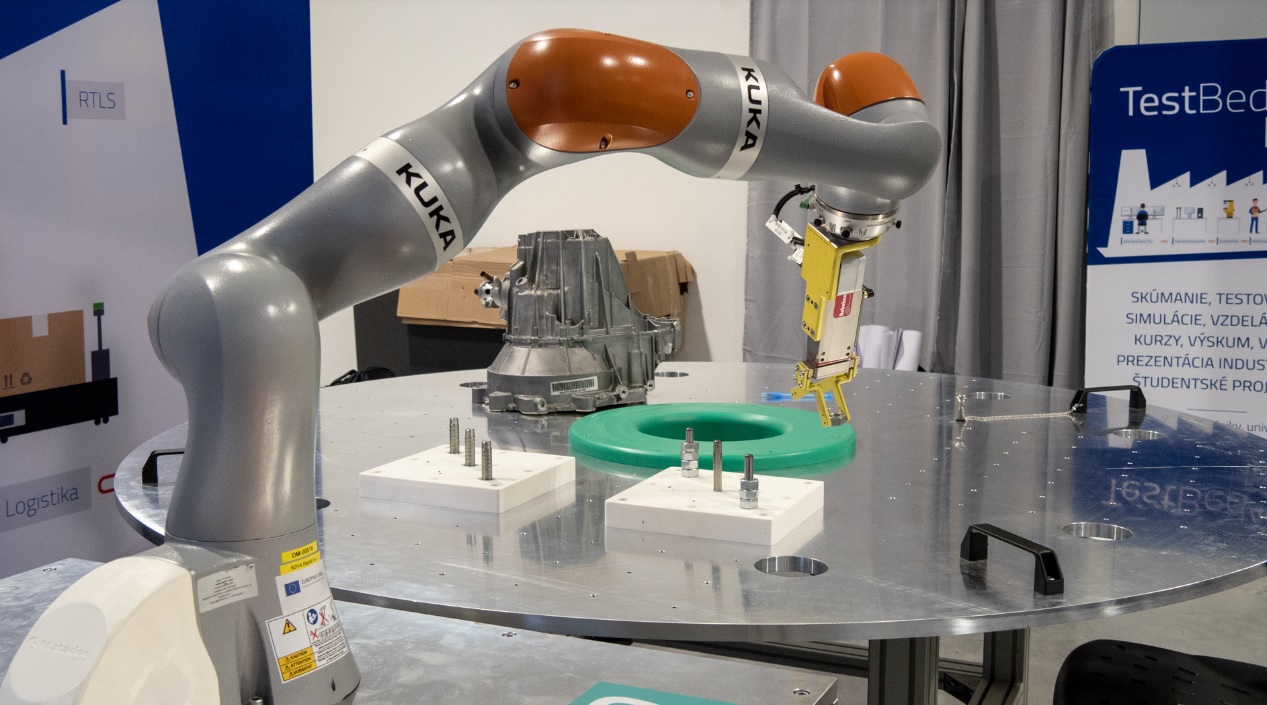

The first TestBed 4.0 in Slovakia

Responsible persons: employees of Sova Digital, for FME TUKE: prof. Ing. Peter Trebuňa, PhD., Ing. Marek Kliment, PhD.

Location: Park Komenského 9, PK9, ground floor no. 001

Addressing the practical needs of industry in the field of Industry 4.0

TestBed provides services for industry that enable businesses to design, test, and optimize Industry 4.0 application solutions tailored to the individual needs of each business and process. The workplace enables the creation of a number of variants of solutions in laboratory conditions very close to reality, which can be verified in a digital environment and the most suitable one can be implemented into real operation. Businesses thus avoid many risks and are able to quickly, and efficiently design, validate, and implement innovations in their operations. TestBed 4.0 is designed for a very wide range of situations and applications of digitization of common and specific needs of every industrial enterprise.

Educating students and involving young talented people in solving the practical needs of practice

The industry is in dire need of a number of Industry 4.0 experts and will need to grow over time. The aim of TestBed 4.0 is to combine theoretical education with the possibility of creating practical experience, and thus strengthen the professional readiness of graduates. TestBed 4.0 expects the industry to be involved in listing the topics of final theses or small commercial projects that can be solved independently by students or under the guidance of TestBed specialists. Students are also considered to be doctoral students, whose expertise usually guarantees the ability to solve even more complex tasks independently.

Subjects

- Modeling and simulation of logistics processes.

- Logistics business processes, process modeling and simulation.

- Digital enterprise.

- Digital, virtual and intelligent races.

- Digitization and virtualization of production.

Resp. person: doc. Ing. Miriam Pekarcikova, PhD.

Location: Komenského Park 9, 3rd floor no. d. 301

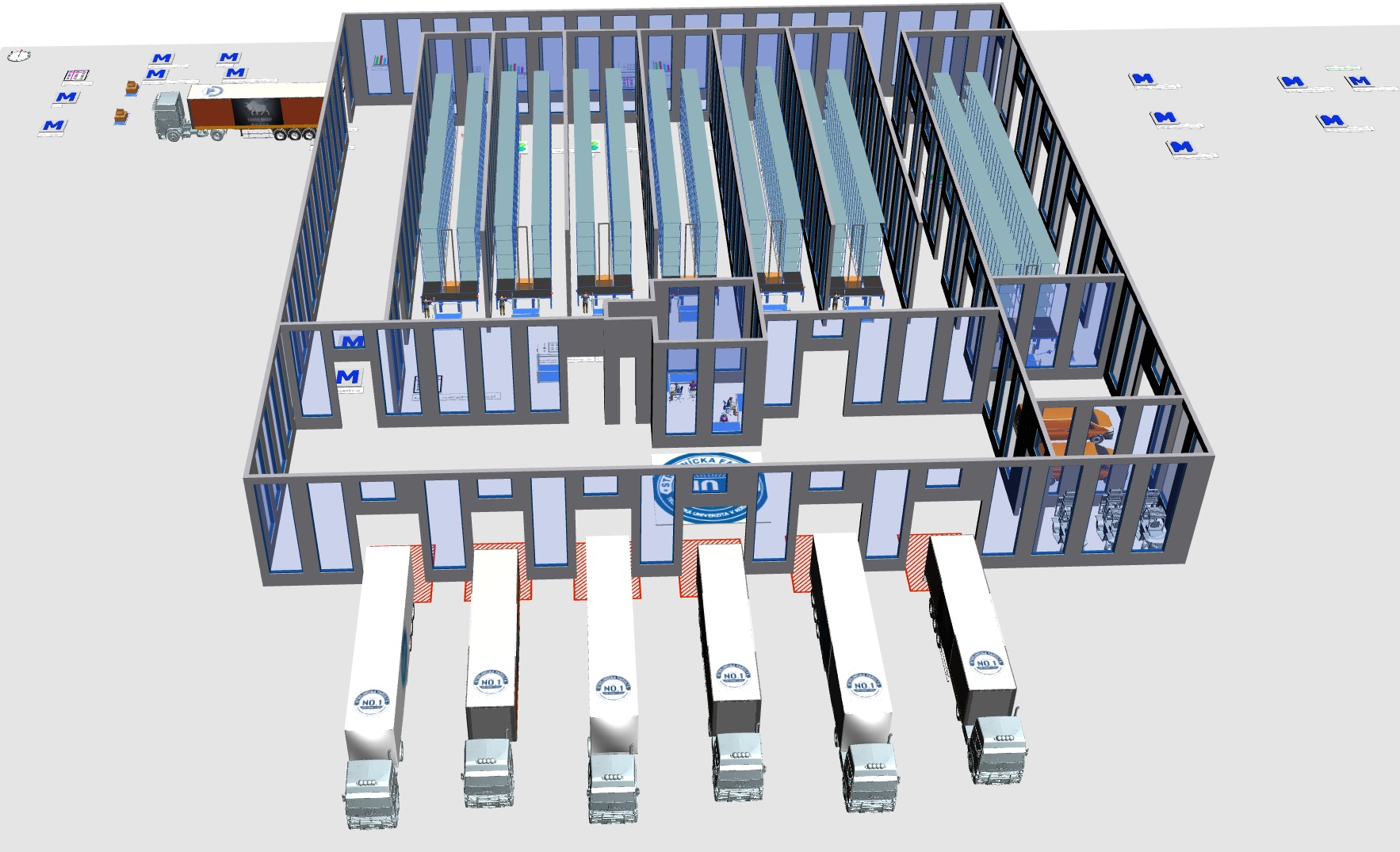

Today, the importance of the Industry 4.0 concept is gaining prominence in every, not just industry. The importance of this idea in this case is based on the principle of intelligent factories and the problems that naturally accompany them. These are mainly elements of digitization, simulation, optimization, but also the independent implementation of these technologies in older companies. The importance of these concepts is gaining more and more prominence due to the ever-increasing form of demands for competitiveness, thanks to which companies are profitable and prosperous. Another important part is the form of creating digital twins using visualization, which creates a digital model of, for example, a manufacturing company or its individual parts.

To solve these problems, a top laboratory of augmented and mixed reality was built, which is equipped with the latest software as well as hardware technologies, which provide students with quality and valuable teaching. As a result, students will develop their creative and technical thinking, the ability to make logical decisions and analyze important aspects that will affect the final results of their work.

Laboratory focus

The laboratory of augmented and mixed reality is mainly dedicated to the creation of a digital image of a manufacturing company or its selected parts, using various software platforms, which have a unique role in this process.

The focus of the laboratory is divided into three basic parts:

- creating digital models,

- creation of dynamic animations,

- simulation of production and logistics systems and their processes.

Students can apply their knowledge in these areas and can create simulation models of production lines, processes or even transport thanks to the dynamic simulation module from Siemens-Technomatix Plant Simulation and then look for ways and possibilities for a specific form of production process optimization. In cooperation with the practice, students are able to create simulation models of production on real layouts and thus check and identify bottlenecks, define the utilization of individual workplaces / operators or determine the throughput of the system. To create a digital model of a manufacturing company, modeling software such as Solid Works or Factory Design is used in this laboratory, where the student can design and model his own version of the manufacturing company.

The laboratory is largely dedicated to the creation of dynamic animations and static (photorealistic) images, which help to complete the compact image of the manufacturing company thanks to the Twinmotion software platform. Within this platform, the student can also model the display of the selected production space and thus create its variations and modify the views of the display as needed. Designed with a simple, intuitive user interface, it makes learning and work easier. In addition, Twinmotion creates high quality images and animations in real time.

Laboratory goals

- Creating simulation models in a software environment with subsequent verification.

- Work on solving simulation problems.

- Creation of dynamic animations for the purpose of visualization of selected production objects.

- Gaining knowledge from practice through layouts when creating digital models.

- Extension of theoretical and technical knowledge of students in the subject area of digitization, software and hardware support.

- To deepen students' abilities in the process of correct decision-making and analysis.

- Creation of student final theses in the subject area.

- Cooperation with practice.

Laboratory equipment

- Oculus Rift S headset - 10 headsets for mixed and virtual reality

- Acer Nitro N50-610 Gaming -10 powerful computer sets

Laboratory software

- Solid Works

- Twinmotion

- Technomatix Plant Simulation

Subjects

- Applied virtual reality.

- Digitization and virtualization of production.

- Control digitization.

- Digital and virtual technologies.

- Digital enterprise.

- Logistics business processes, process modeling and simulation.

- Modeling and simulation of logistics processes.

- Basics of digital and virtual technologies.

Responsible person: prof. Ing. Peter Trebuňa, PhD.

Location: Komenského Park 9, 2nd floor, no. d. 206

Laboratory focus

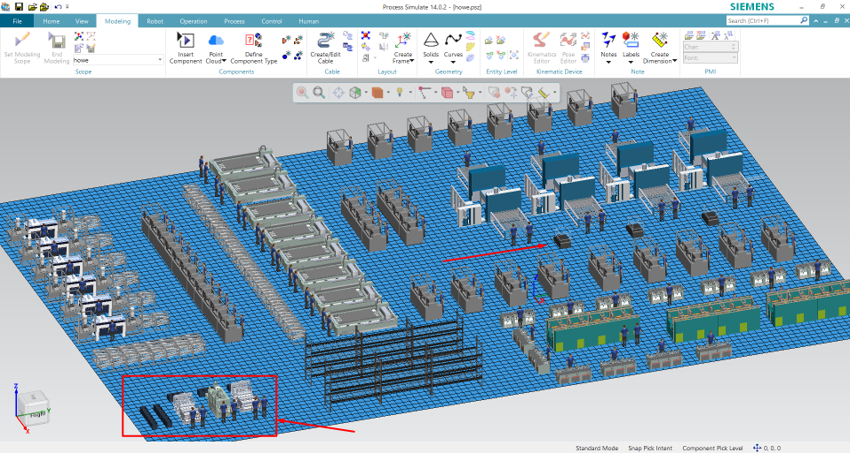

Managing business processes is one of the main pillars of a successful company. In the laboratory, students research production and non-production processes and, within the framework of digitization and simulation, create solutions for streamlining business processes. The laboratory is equipped with 10 modern computers, on which students solve the assigned problem, an interactive touch board with a projector and a SMART screen. Teaching is realized in software programs. The most used are Tecnomatix Plant Simulation and SolidWorks. In the Tecnomatix Plant Simulation program, students solve logistics processes, the company's supply activities and the optimization of the company's production process. Modeling of 2D and 3D models is realized by teaching in the SolidWorks program, where the student will gain considerable experience with modeling and simulation. Process Simulate is another software tool used in the teaching process. Process Simulate is a digital manufacturing solution for verifying the manufacturing process in a 3D environment. Process Simulate is a key tool for rapid time-to-market by allowing you to virtually validate production concepts in advance - throughout the new product launch lifecycle. The ability to leverage 3D product and resource data facilitates virtual validation, optimization, and execution of complex manufacturing processes, leading to faster startup and higher production quality. Students will test their proposed improvements in production processes. When working with SolidWorks software, they will use theoretical knowledge from subjects as the basis of construction.

Laboratory goals

- connection of theoretical knowledge with translation studies,

- improving the productivity of existing equipment from practice,

- calculation and reduction of unnecessary stocks and production time.

- 3D modeling and its application in practice or further use of models for 3D printing and the creation of prototypes or models of production machines and tools.

- developing cooperation and creativity between students in solving collective tasks.

Laboratory equipment

- 10x computer HP OMEN Obeliskc875-1020nc,

- 1x CTOUCH Riva,

- 1x Interactive touch panel,

- 1x EPSON EB- 695 Wi.

Subjects

- Digitization and virtualization of production.

- Digital and virtual technologies.

- Digital enterprise.

- Logistics business processes, process modeling and simulation.

- Modeling and simulation of logistics processes.

- Basics of digital and virtual technologies.

Responsible person: Ing. Juraj Kovac, PhD.

Location: Komenského Park 9, PK9, 2nd floor no. 210

The virtual and mixed reality, given that it is a relatively new area, also requires adequate research and development laboratories or workplaces. The workplaces of such laboratories must be equipped with state-of-the-art technical and software resources, information and the necessary knowledge. The creation and construction of laboratory workplaces used for such experimental activities requires a collaborative approach, good cooperation, coordination in solving problems and project tasks, high awareness, good access to various sources of information. Project activities related to the design and implementation of laboratory workplaces of virtual and mixed reality are based on long-term strategic directions of development of the FME TU in Košice.

Laboratory focus

The laboratory focuses on teaching the creation of digital models and their implementation into virtual reality. It is equipped with software and hardware resources. Software includes CAD systems such as SolidWorks, Inventor Professional, Autocad, Factory Design, and twin reality software Twinmotion and Pixyz Review. Students will gain practical experience in creating 3D models and creating virtual scenes and designing production systems in 2D and 3D views, which can then be visualized and displayed via hardware equipment such as HMD Oculus Rift display, Cyber Glove 2 data gloves, holographic projector and multi-touch projection. table.

Laboratory goals

Gain practical experience in creating 3D models in CAD systems and design production sites in 2D and 3D views.

Learn to implement 3D models into virtual reality and create virtual scenes and simulations.

Get acquainted with the means of virtual reality such as HMD display, data gloves, holographic projector and 3D scanning.

Laboratory hardware

. PC workstations in the number of 14 pieces

. HMD Display Oculus rift

. Cyber Glove II data gloves

. Holographic projector

. 3D scanner

. 3D projector

. Multi-touch projection table

Laboratory software

. Factory Design Utilities

. Atocad

. Professional Inventor

. SolidWorks

. Twinmotion

. Pixyz Review

Subjects

- Applied virtual reality

- Design of production systems

- Design of engineering productions

- Design of production processes

- Design and convert production systems

- Production automation

Responsible person: doc. Ing. Vladimir Rudy, PhD.

Location: Komenského Park 9, 2nd floor no. d. 207

Designing is an important part of activities carried out in industrial production in the whole range of economic life. They include day-to-day production innovations in line with changing market requirements, which places an enormous burden on the need to reorganize and modernize production groups. The implementation of these processes is unthinkable today without the use of SW and HW technology, which guarantees high flexibility, time dynamics and economic efficiency of the implementation of these changes. Acquisition of these design methodologies is a guarantee that the graduate, after entering the practice, is fully prepared for the implementation of these processes in the conditions of industrial practice.

Laboratory focus

In the design studio of industrial plants and enterprises, several specific devices (eg 3D scanner and 3D camera) as well as common ICT equipment (eg interactive whiteboard) are currently used in educational activities. As part of its equipment, the studio also has other specific equipment that can be used in the teaching of subjects such as: Production preparation, Design and operation of production systems and Design of companies. The basic focus of the studio is to acquire and deepen knowledge in the field of designing modern customer-oriented productions, modernization of obsolete productions and innovations in the production of engineering productions. In the laboratory, teaching is provided mainly for ending students of bachelor's and engineering studies in the subjects "Production design, Design and operation of production systems and Design of companies".

Laboratory goals

- to teach students the basic approaches of 3D modeling techniques - CAD,

- to teach students to master the basic methodologies of the distribution of production technology and the principles of creating higher production groups,

- spatially optimize production groups, resp. deployment,

- optimize material flows and solve storage spaces,

- learn the main principles of methodologies for selecting production technology,

- to master the basic principles of designing production groups of productions of the future,

- to master the principles of production implementation on the principles of ergonomics, resp. environmental studies.

Laboratory hardware

- 2 PC stations,

- dron DJI Mavic Pro Fly More Combo + DJI,

- 3D scanner SCAN in a BOX Structured Light,

- Tamaggo 360 LiveCam 3D camera.

- Laboratory software

- Inventor,

- Catia,

- AutoCad Factory Design.

Subjects

- Modern processing technologies.

- Basics of engineering production design.

- Business processes and systems.

- Business strategies.

- Advanced industrial engineering.

- Production preparation.

- Design and operation of production systems.

- Business design.

- Design of engineering productions.

- Design of production processes and systems.

- Project management.

- Production management.

- Theory and methodology of designing business processes and systems.

Mikrolaboratórium slúži najmä účelom výučbového a výcvikového procesu študentov Bc., Ing. a PhD. v študijnom odbore Priemyselné inžinierstvo v oblasti osvojenia si najmodernejších hardvérových a softvérových prostriedkov súčasnosti. Taktiež slúži na podporu a rozvoj vedeckých aktivít Ústavu manažmentu, priemyselného a digitálneho inžinierstva.

Hlavný účel laboratória:

1. skenovanie fyzických objektov menších rozmerov do digitálnych modelov v počítači

2. úprava vlastností digitalizovaného modelu za pomoci 3D podporných softvérových nástrojov

3. poskytovanie porovnávacích meraní skutočných a vytlačených objektov za účelom tvorby dokumentácie

4. skenovanie človeka (pracovných pozícií) vo výrobe za účelom optimalizácie parametrov ergonomických analýz priamym

meraním pomocou pohybového senzora Kinect v.2 a softvérového modulu SIEMENS Jack & Jill.

Vybavenie laboratória (hardvér):

1. Pracovná stanica pre spracovanie digitálneho obrazu

2. Notebook HP Professional

3. 3D skener - Matterform

4. 3D tlačiareň - 3D Factories EasyMaker čierna 0.5mm

5. 3D HD projektor Benq W1070 DLP

6. Pohybový snímač - Kinect for Windows v2 Sensor Full HD so statívom

7. Fotoaparát Canon EOS 550D

8. 3D Full HD kamera Sony HDR-TD10.

|

|

|

|

|

|

|

|

|

Our address: Working time: Mon - Fri: 8:00 - 16:00

Faculty of Mechanical Engineering

Department of Industrial and Digital Engineering

Park Komenského 9

042 00 Košice

Slovakia

For students

In this section you will find a link to interesting offers published on the website of the Technical University in Košice for students.

MAIS portal

When looking for a syllabus of study subjects, it is advantageous to know a web link to the MAIS portal maisportal.tuke.sk/portal/.