Welding, joining and surface treatment

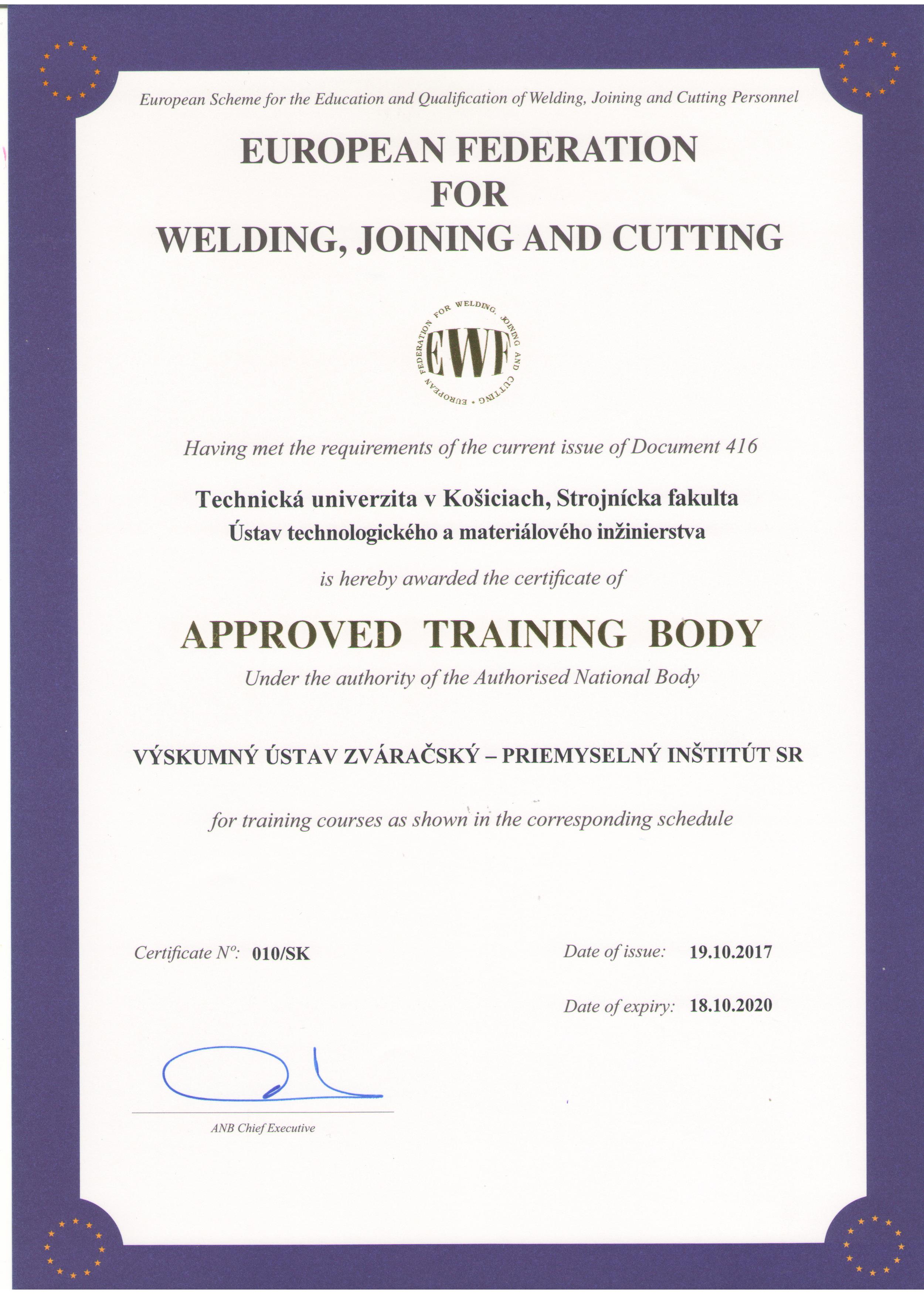

Graduates of the study programme Welding, joining and surface treatment are able to systematically and comprehensively solve practical tasks in the field of methods and technological procedures of welding, joining and surface treatment. They have knowledge of conventional as well as special welding technologies, alternative joining methods, surface pretreatments and surface treatments. They have knowledge in the field of technical materials, including progressive ones, their sleep during welding and heat treatment. They can analyze the quality of joints and surface using control methods. In addition, they can use information technology in solving the tasks of the department and also apply knowledge and skills in laboratory work. Graduates can work in engineering companies as technologists specializing in welding, respectively surface treatment, production coordinators, quality controllers, after completing the education also in the positions of welding engineers, resp. certified personnel in NDT, in the administration of pre-production stages, sales representatives and sellers of machinery and equipment. They can also be used as researchers in research and development centers, research institutes in the Slovak Republik, resp. abroad. The study program is highly topical due to Slovakias orientation towards automotive production, in which the methods of welding, joining and surface treatment belong to the dominant production technologies.

The graduate of this study program is able:

- to solve practical tasks in the field of methods and technological procedures of welding, joining and surface modification,

- conventional and special welding technologies, alternative joining methods, surface pretreatment and surface treatment, corrosion protection of construction materials,

- analyze the quality of joints and surfaces using control methods,

- use information technology in solving the tasks of the department and apply knowledge and skills in laboratory work.