Engineering Technologies

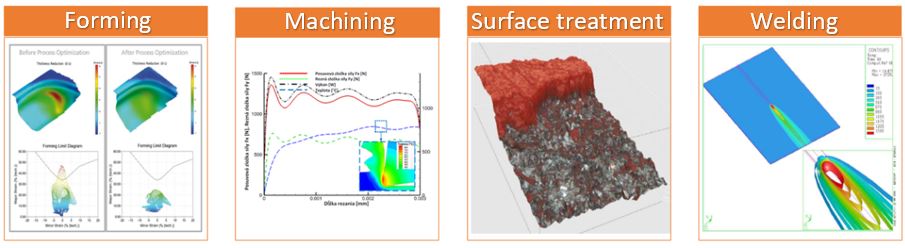

The study program is focused on the preparation of experts for the performance of engineering functions in the companies of the engineering, electrical and consumer industries in technical and managerial services, in the field of design, provision and management of production. Teaching in this study program is aimed at gaining theoretical knowledge, experimental and practical experience, knowledge of performance and processability of materials according to machinability, formability and weldability, knowledge of conventional and unconventional materials, processing technologies sucg as machining, forming, welding, electrochemical, electroerosive technologies, etc., further knowledge of the construction of the tools and jigs with the support of PC and the application of CAD/CAM/CAE systems in product design and production. A key and inseparable part is the optimization of technological production processes and products for specific technical and economic conditions of the production.

Graduates of the study programme Engineering Technologies are on the basis of the acquired knowledge, able to coordinate engineering production and solve current practical tasks. In addition to that, they have the knowledge of conventional and progressive engineering technologies, technical materials, knowledge of engineering production computer support, testing, design, as well as foreign language proficiency.

The graduate of this study program:

- acquire knowledge of the conventional and unconventional technological processes of the production of semi-finished and finished parts,

- acquire knowledge of the principles of the designing tools and preparations, their economical use and management,

- acquire knowledge of the principles of effective design on the semi-finished and finished parts,

- can analyze product errors and propose technical solutions to eliminate them with a high degree of the creativity and independence,

- acquire knowledge and practical experience on the principles of the product assembly, handling, transport and storage of the components within the production process,

- acquire knowledge of the production machines and equipment,

- can design and evaluate experiments in order to optimize the choice of the material, tool geometry and parameters of technological processes,

- can design and manufacture components on numerically controlled production machines and equipment,

- can creatively and systematically analyze technological processes,

- can verify mathematical - physical models of the technological processes based on the experimental tests,

- acquire knowledge to use CAx technologies in production design and management,

- acquires the ability to independently solve the problem of the technologiacl design of the production processes and systems on the basis of complex and systematic relationships of the individual technologies according to the requirements of integration, automation and efficiency of production processes,

- acquires sufficient knowledge of economics and production management in the pre-production stage so that he can find application in management and operational positions in enterprises of the mechanical engineering, electrical engineering, consumer industry, etc.