Katedrovica_PPSV_2025

On 04.03.2025, an event called Katedrovica was held for our students from the PPSV Ing. 1st and 2nd year study programme. We would like to take this opportunity to thank you for the awesome atmosphere and great fun.

fotogaléria: Katedrovica_PPSV_2025

KSIT 2024 International Scientific Conference

From 02 to 05.11.2024 the KSIT 2024 conference was held in Tály, Slovakia. It brought together experts from metallurgy, metallurgy and industry from Slovakia, the Czech Republic, Poland and Romania. The event was also a celebration of the thirtieth anniversary of the scientific journal Acta Metallurgica Slovaca.

Photos

Erasmus scholarship for PhD studies, year 2024

Ing. Samuel Vilkovský took part in a one-month Erasmus+ Traineeship at the Faculty of Mechanical Engineering, University of Ljubljana, Slovenia, which broadened his knowledge with additional academic opportunities. Within the framework of the above-mentioned stay at this faculty, he also focused on future scientific cooperation with this university in the field of forming under the guidance of prof. Pepelnjak. He extended his previous knowledge in the field of simulation of forming processes by the possibilities of using Neural Network and Random Forest methods, which contributed to a new insight into new modern research techniques and methodologies. His further experience from his stay at the University of Ljubljana Mr. Ing. Vilkovský can be read by clicking on the link below.

ERASMUS scholarship

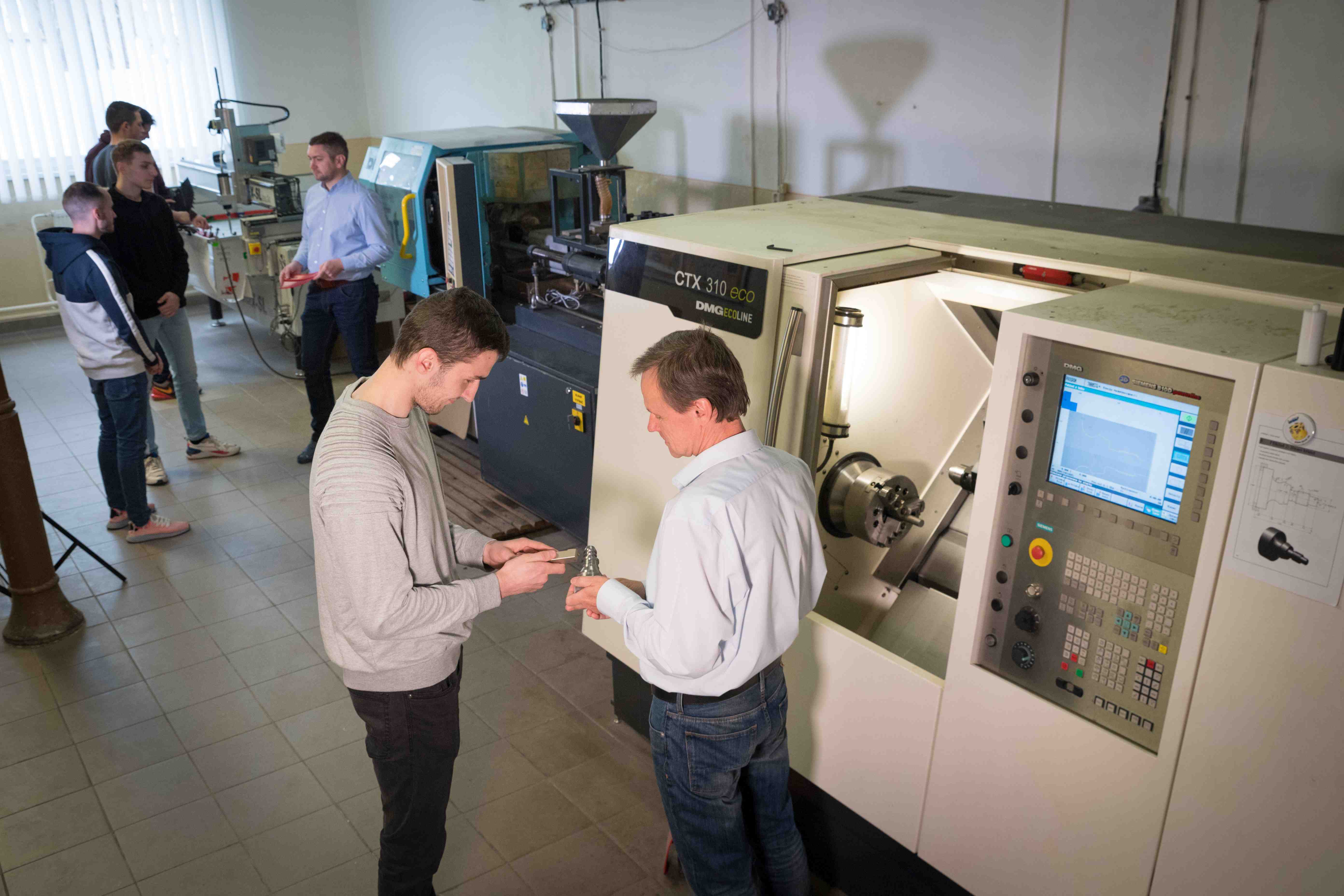

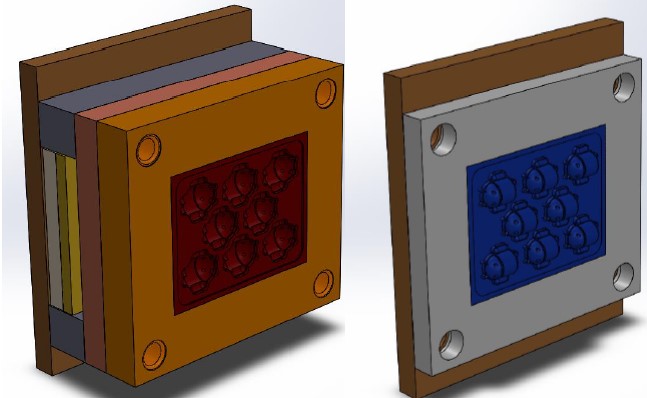

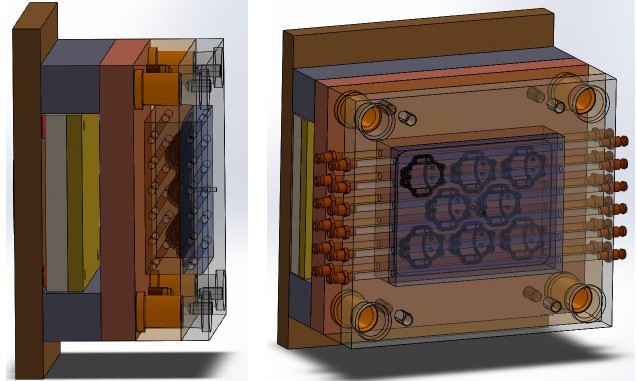

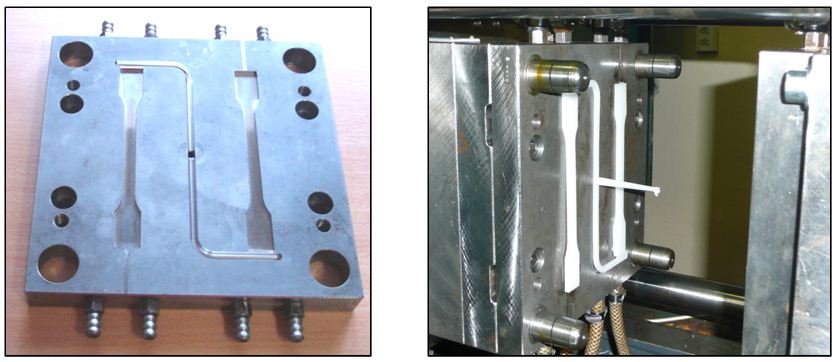

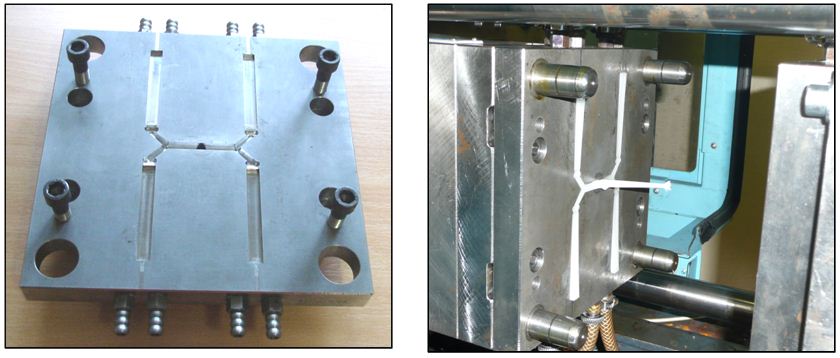

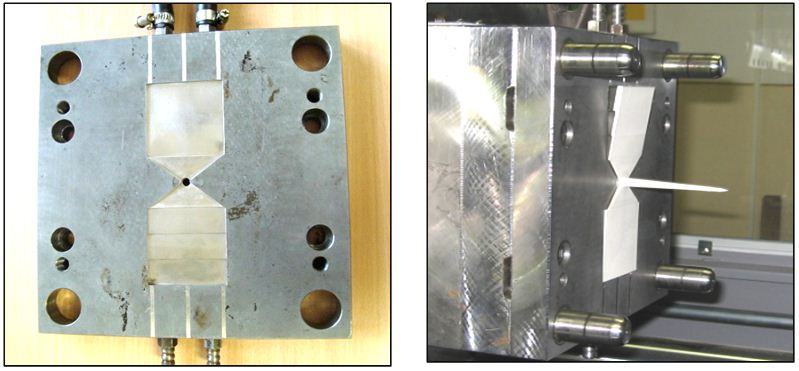

RoadShow Sumitomo DEMAG

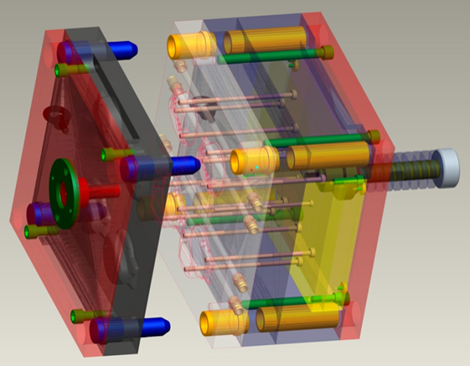

On 21.05.2024 company Sumitomo DEMAG representatives visited the Institute of Technological and Materials Engineering at the Faculty of Mechanical Engineering of TUKE. This company presented cutting-edge solutions in the field of plastic injection moulding technology, including a real demonstration on an injection moulding machine. The presentation was intended for employees of the Institute of Technological and Materials Engineering, as well as for students and representatives of various companies from KE and the surrounding area. With her expertise in the field of plastic injection moulding, she pointed out the latest trends, tools as well as functions and control panels showing the entire injection moulding process. One of the many features was an introduction to the so-called activeMeltControl function, which adapts the injection moulding process to changes in material (including regranulate), automatic pressure adjustment, or correction of moulding weight fluctuations.

photos

Visit of Volvo Cars

On 14.02.2024 Volvo Cars visited the Institute of Technological and Materials Engineering at the Faculty of Mechanical Engineering, TUKE. They were interested in study programs oriented on the issue of automotive production, scientific and research activities and possibilities of further cooperation. There was a discussion about the possibility of applying our graduates within the company. A number of study programmes of our faculty offer a wide range of graduates who can find employment in the newly created company in Valaliky Industrial park. In the coming period, representatives of Volvo Cars will visit the laboratories and workplaces of the Faculty of Mechanical Engineering.

photo from the visit: Volvo

International Scientific Conference PRO-TECH-MA 2023 and Košice Innovation and Technology Summit KSIT 2023

An international scientific conference was held in Herľany on 06-08.09.2023.

photo from the conference: PRO-TECH-MA 2023

Visit to RF Elements company

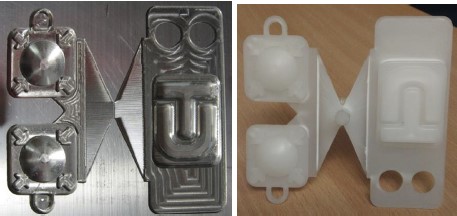

On 27.06.2023 an excursion was held for the students of the PPSV Ing. studies in the company RF Elements in their development and production centre at the city of Humenne.

photo from the excursion: RF elements

CEEPUS Summer School 2021

As part of the CEEPUS scholarship program, KTMaPPV students completed a study stay at Politechnika Svietokrzyska in KIelce, Poland. As part of their two-week stay, they had the opportunity to take interesting lectures, visit the laser technology center, several laboratories, but also get to know the city and its surroundings in free time. As part of the summer school, they also visited the 25th year of the exhibition PLASTPOL

YOu can find more photos in photo gallery: letná škola CEEPUS 2021

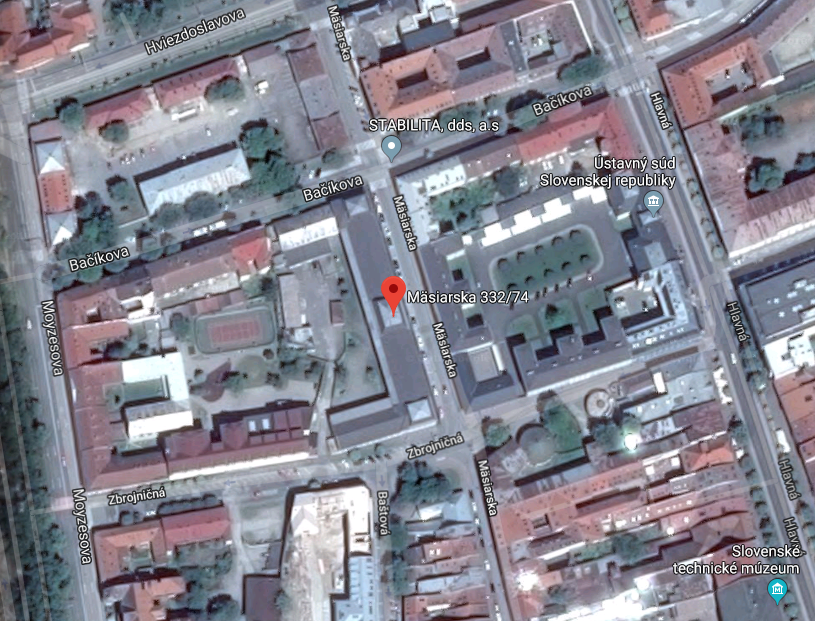

Revitalization of the KTMaPPV

During the summer months, the premises of the Department of Technology, Materials and Computer Aided Production on Mäsiarska street were renovated.

More photos you can find in the photo gallery: revitalizácia priestorov KTMaPPV

PRO-TECH-MA 2020

An international scientific conference (venue of Rzeszów) was held on 21 October 2020. For more information, visit

https://protechma2020.prz.edu.pl/main-page

Summer school CEEPUS

The students of the 2nd year of engineering studies of the PPSV study program completed a study stay at the University Politechnika Świętokrzyska in Kielce, Poland, within the CEEPUS scholarship program. During the two-week stay, they had the opportunity to attend interesting lectures, visit the laser technology center, but also get to know the city and its surroundings in their free time.

fotogaléria zo študijného pobytu

PRO-TECH-MA 2019

An international scientific conference will take place in Herľany from 15 to 17 September 2019. All interested parties from Slovakia and abroad are invited. More information can be found at:

https://www.sjf.tuke.sk/kstam/protechma/

Open Door Day 2019

Fotogaléria deň otvorených dverí

On March 20, 2019, an event entitled ,,Open Day" was held in the University Library of the Technical University in Košice, which was attended by the general scientific and lay public as well as students and teachers of secondary schools. As part of the Open Day event, employees of the technologies and materials informed about the possibilities of studying the Bachelors study program Technology, Management nad Innovation of Mechanical Engineering as well as about the knowledge that students can acquire and then apply in practice after studying other study programs at KSTaM.

HORIZON 2020 - NEWEX project

HORIZON 2020 - NEWEX project

Fotogaléria

On February 25-26, 2019, a management meeting and workshop was held at KSTaM within the international project NEWEX entitled „Research and development of a new generation of machines for processing composite and nanocomposite materials“, where the design and production of a new innovative extruder is concerned. The implementation of this project supports real cooperation between industry and education, which is of key importance for the European research development strategy.

STEEL Park

Kreatívna fabrika

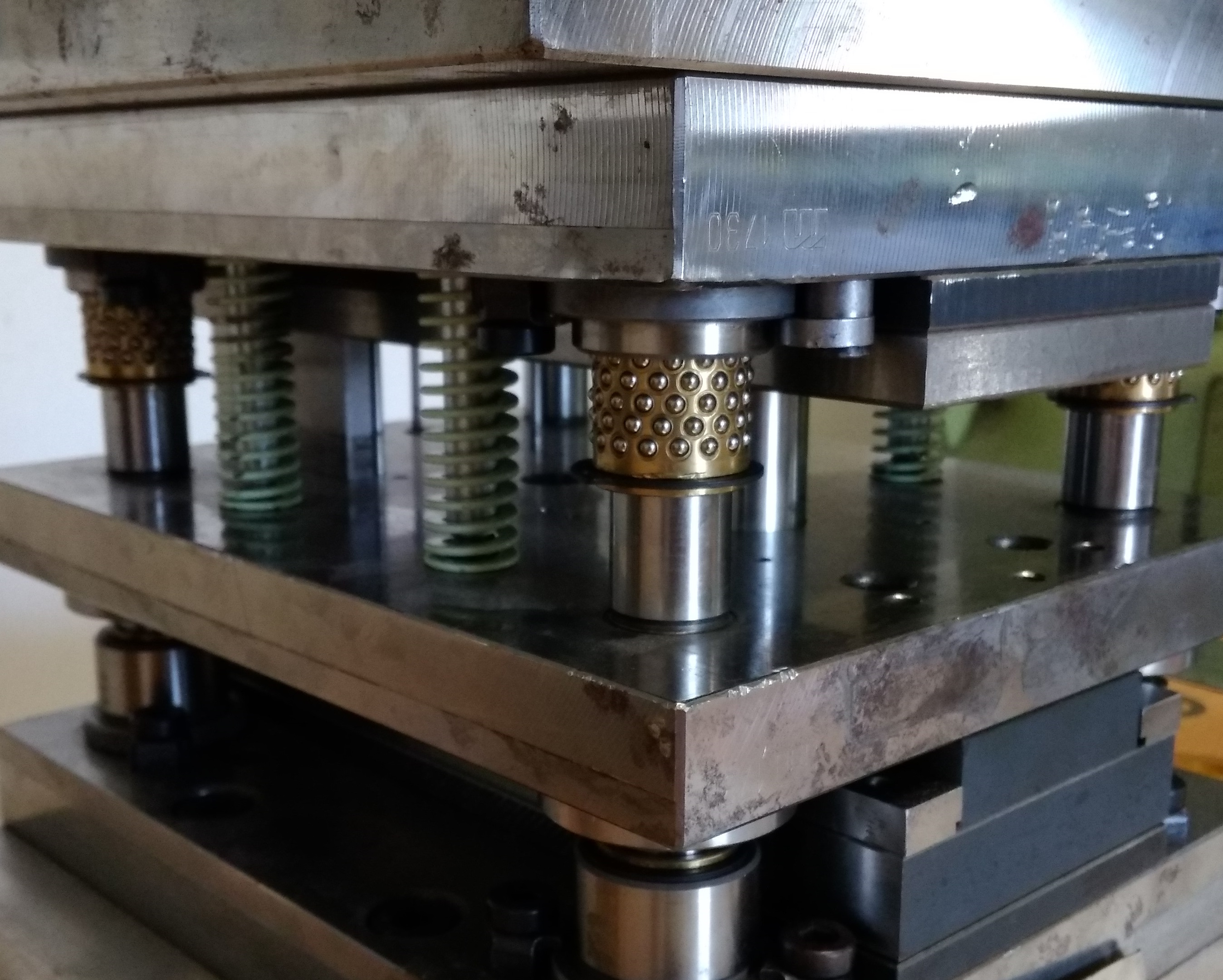

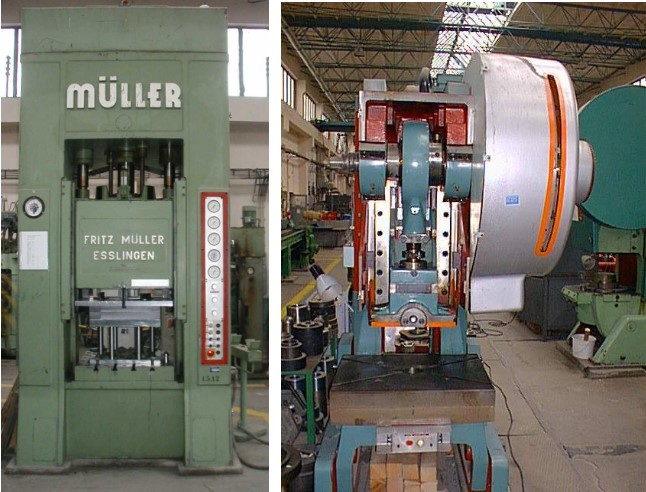

At our department under the leadership of prof. Ing. Emila Spišáka, CSc. and Ing. Juraja Hudáka, CSc. as well as the other educators, employees and students and the guarantor of the project U.S. Steel Košice was gradually prepared and realized one of the exhibits - the production of a toy car from sheet steel.

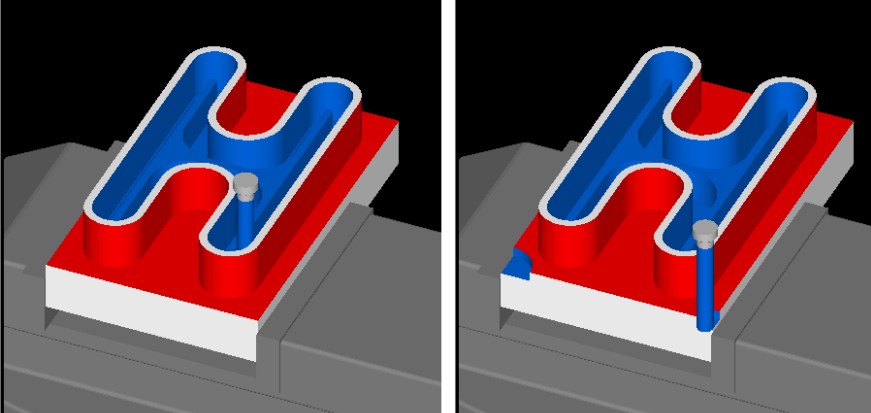

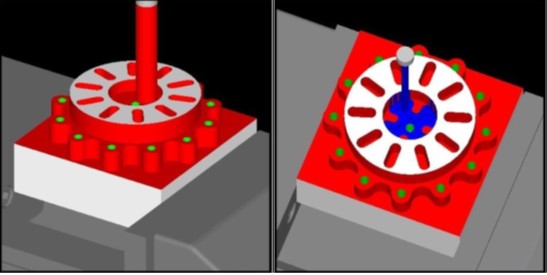

Competition

Fotogaléria

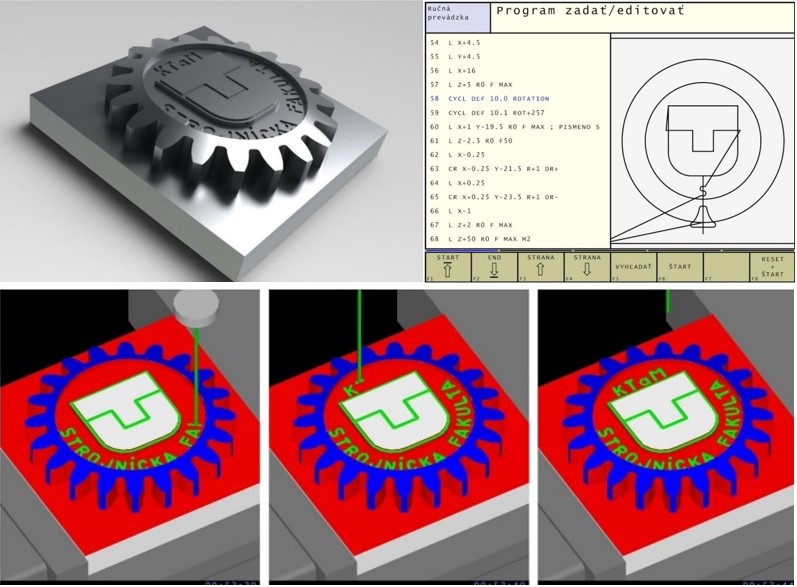

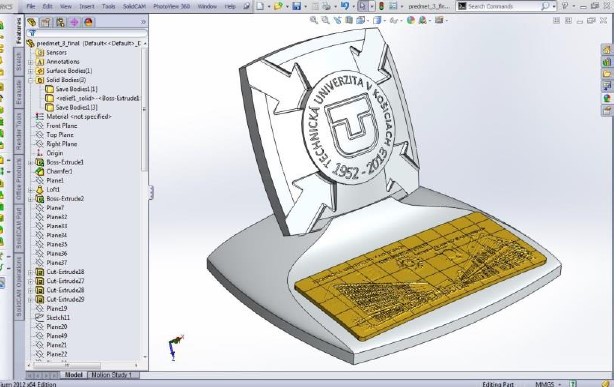

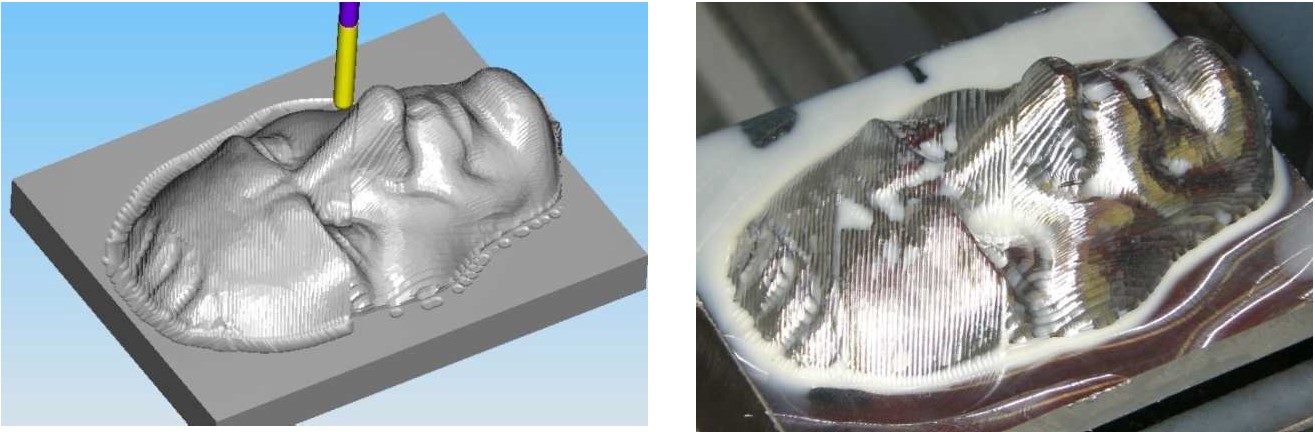

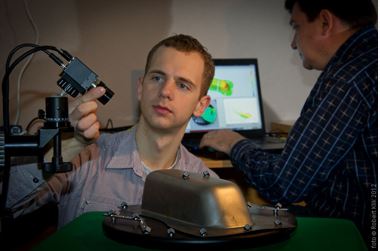

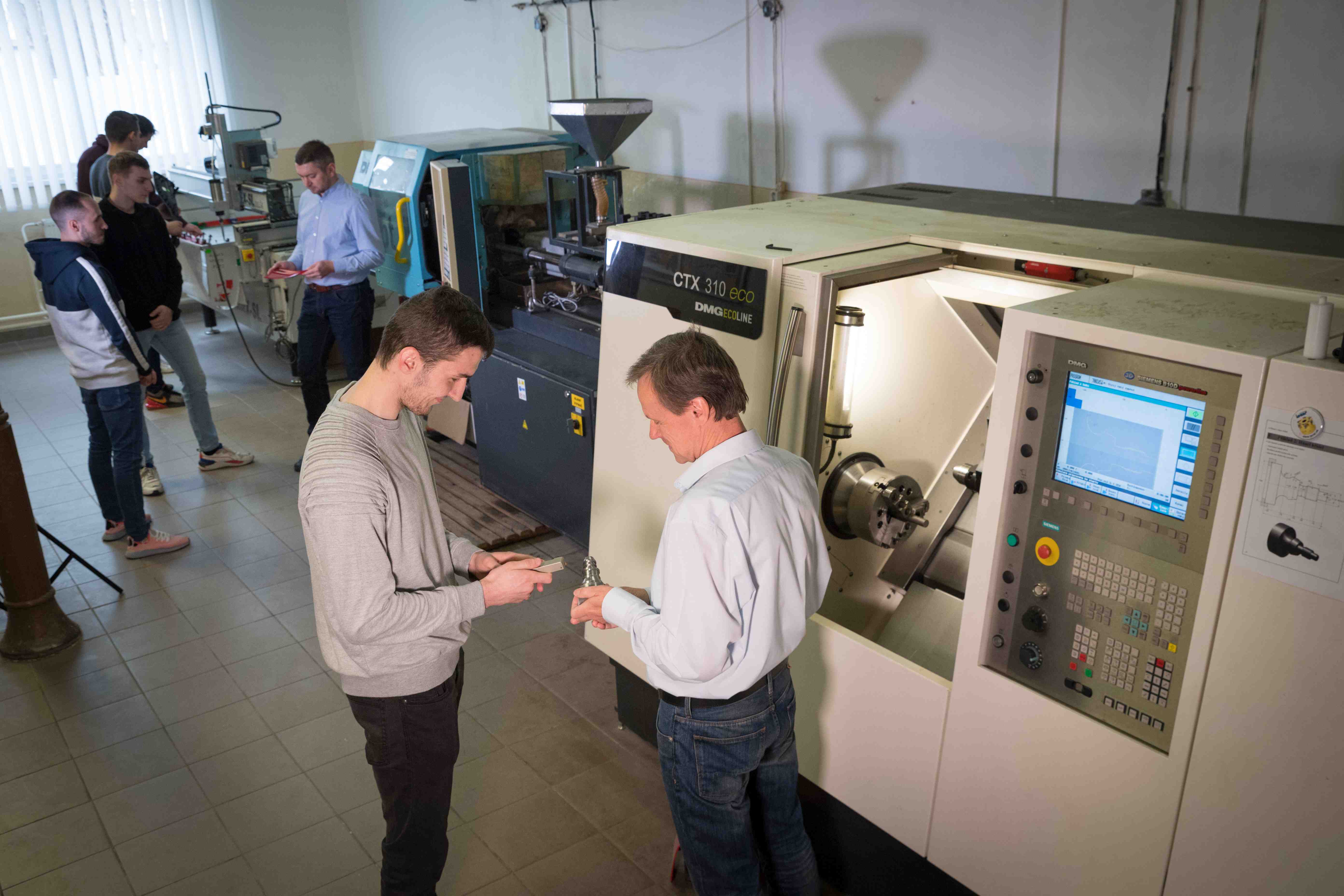

On March 19, 2015, a competition of FME TU students in CNC machine programming took place. It was prepared by the Department of Computer Aided Technologies and the Department of Mechanical Engineering Technologies and Materials under the auspices of the Dean of the Faculty of Mechanical Engineering Dr.h.c. mult. prof. Ing. Františka TREBUŇU, CSc.

Conference

On 7 and 9 October 2015, the international scientific conference Pro-tech-ma 2015 and Surface Engineering 2015 took place, organized by the Department of Mechanical Engineering Technologies and Materials in cooperation with the universities of the Rzeszow University of Technology and Polish University of Technology. The conference took place at the Hotel Hubert in Gerlachov in the High Tatras.