Welding and Defectoscopy Laboratory (M74-036)

Responsible person: prof. Ing. Ján Viňáš, PhD., IWE, EWE

Location: Mäsiarska 74

Focus of the laboratory

The laboratory focuses on the research of cutting, soldering, welding, welding of materials as well as the evaluation of the quality of welded joints. It is aimed at gaining practical experience in flame welding, manual arc welding, MIG/MAG/TIG welding and resistance welding. The laboratory is also designed as a training facility (Welding School) for manual arc welding in accordance with STN 05 0600 and STN 05 0630, consisting of four teaching boxes and one instructor's station. At present, the laboratory contains equipment used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and dissertation theses in the department. The laboratory is used for teaching non-destructive methods of weld testing. NDT quality control of welded joints is carried out by means of visual and capillary testing. The professional focus of the laboratory is the optimization of welding processes and the investigation of the quality of welded joints.

Laboratory equipment

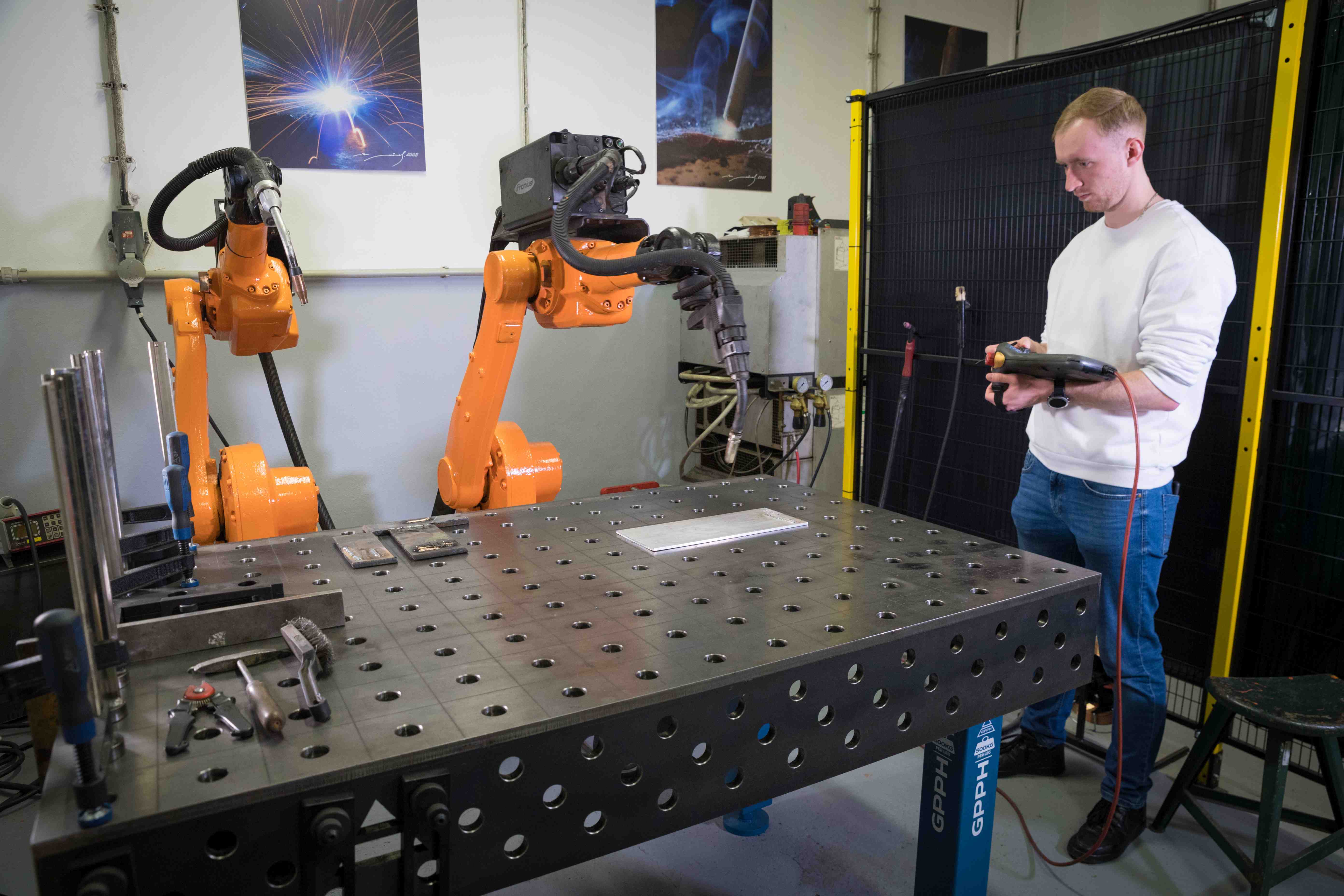

Welding equipment Fronius MagicWave 4000 Job, WTU 600, KSM 100, EssetyMiny, Formica 169, CLOOS MC 303 and pneumatic spot welder VTS BPK 20. The laboratory also includes a tandem robotic welding workplace equipped with two ABB IRB 1600 robots in interaction with Fronius TransSynergic 4000 and SKS welding machines, enabling welding with MIG/MAG methods as well as with the progressive CMT (Cold metal transfer) method.