The Department of Automotive Production (DoAP) is a part of the Institute of Technological and Materials Engineering of the Faculty of Mechanical Engineering of the Technical University in Košice. Currently, the teaching area of the department is focused on the study programme Automotive Production. The subjects are mainly focused on technologies and processes of automotive and automotive components production, product design and innovation, testing and certification. It includes the application of CAx technologies in both product design and manufacturing processes and workplaces.

Research and development within our workplace is oriented to technology, product design, automotive production organization, application of lean manufacturing and assembly methods and tools.

Education and training of students focusing on the preparation of professionals for the positions of project manager, fixtures, jigs and products designer, process engineer and test engineer in the automotive industry. Graduates will gain knowledge in the field of automotive production management (economics and production management, quality management and logistics in the automotive industry).

The research is focused on the construction of ultra-lightweight cars using alternative energy sources, development and application of new advanced metallic, polymeric and composite materials, modelling and simulation of technological processes of production and assembly of automotive components and their testing.

The projects solving focused on the implementation of reverse and simultaneous engineering techniques in the development of automotive components and their testing.

Laboratories of the Department

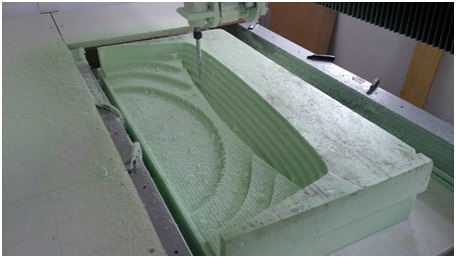

Design and Prototyping Laboratory

The laboratory focuses on product design using state-of-the-art equipment and enables the production of components from composite materials using modern technologies and processes. Currently, the laboratory houses equipment used for scientific and research activities of basic and applied research, as well as for the solution of final bachelor, diploma and doctoral theses at the department: a test bench for testing automotive components, a 3D FARO Platinum Arm measuring arm and laser scanning head and Polyworks Inspector software, a 3D Microscribe touch scanner, workstations for CAD and computer aided innovation for Product Design, equipped with software: Autodesk Maya, Rhinoceros, Adobe Creative Suite, vacuum technology equipment for the production of components from composite materials, inspection microscope 3D optical system ARGUS, powerful workstation for the analysis of results and 3-axis milling / engraving machine Kompas F 3000 suitable primarily for milling plastics, wood, plywood, occasionally: aluminum, brass.

|

|

|

|

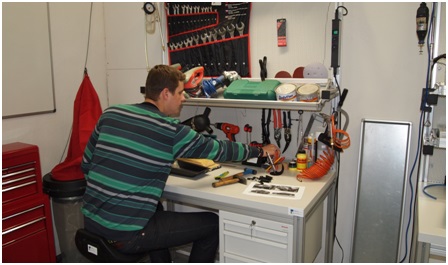

Automotive Testing and Diagnostics Laboratory

The laboratory is oriented towards practical demonstrations of car diagnostics and testing. It is equipped with test benches and measuring equipment for automotive components. The laboratory also includes cars of various factory brands such as Skoda, Kia, Peugeot and BMW, which serve as demonstration models in the implementation of the teaching. The laboratory also includes measuring equipment for diagnosing the functional characteristics and parameters of the car. Students have the opportunity to get acquainted with their function and the principles of diagnostics directly during practical demonstrations and exercises. The measured values are later evaluated and in case of detection of data showing various errors and inaccuracies from the nominal values, they look for the causes of their occurrence and follow the consequences of their action.

LEANLAB laboratory established within the project HUSK/1101/1.6.1/0161: Establishing LEAN knowledge and laboratories

This laboratory is designed for solving problems of manual assembly of products or assembly subgroups of small and medium complexity using methods and tools of lean manufacturing. The concept allows to connect the so-called virtual design with the realization of assembly in the laboratory, integrated application of methods for lean assembly, the possibility of individual application of each method based on the requirements, comparison of the results of the virtual and experimental part. A thorough analysis of the product and the production process through various tools makes it possible to track the progress of assembly operations and obtain a wealth of data to identify value-adding elements (operations or movements), non-value-adding ancillary elements and unnecessary elements that represent waste. Subsequently, training of lean methods such as 5S (workplace or production process layout), Poka-yoke & Jidoka, Just in time, bottleneck analysis, KAIZEN event, training of standardized work improvement and implementation of measures, SMED (e.g. by designing preparations, rearranging operations, etc.) can be initiated. The most commonly used tools in training include A3 report, Yamazumi chart, Ishikawa chart and others.

|

|